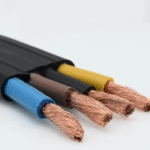

MTW wire, short for Machine Tool Wire, is a type of copper building wire commonly used in control cabinets, machine tools, and industrial equipment. Designed to be flexible and durable, MTW wire meets specific UL and NEC standards for safety and performance in wet and dry locations.

Whether you’re wiring industrial control panels or looking for a flexible option for indoor circuits, MTW wire is a reliable and popular choice.

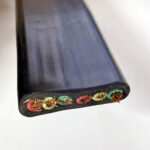

mtw wire

What Does MTW Wire Mean?

MTW stands for Machine Tool Wire. It refers to a thermoplastic insulated, stranded copper wire that is rated for 600 volts and designed to withstand oil, moisture, and mechanical wear. MTW wire is often used in factory machinery and control circuits.

MTW Wire Specifications

Here’s a quick overview of standard MTW wire specifications:

Conductor: Stranded bare copper (Class B or C)

Insulation: Polyvinyl Chloride (PVC), flame-retardant and heat-resistant

Voltage Rating: 600V

Temperature Rating:

90°C in dry locations

60°C in wet locations (per UL standards)

Approvals: UL 1063, CSA AWM I A/B, MTW, and TEW ratings

Standards: UL Listed, RoHS compliant

Common MTW Wire Sizes

We offer MTW wire in various AWG sizes for different current demands. Popular sizes include:

16 AWG MTW Wire – Ideal for low-current circuits in control panels

6 AWG MTW Wire – Used in higher-load applications like motors and power supplies

Looking for detailed electrical capacity? See the MTW wire ampacity chart below.

MTW Wire Ampacity Chart

| Wire Size (AWG) | Ampacity (Dry, 90°C) | Ampacity (Wet, 60°C) |

|---|---|---|

| 18 AWG | 7 Amps | 5 Amps |

| 16 AWG | 10 Amps | 8 Amps |

| 14 AWG | 15 Amps | 10 Amps |

| 12 AWG | 20 Amps | 15 Amps |

| 10 AWG | 30 Amps | 20 Amps |

| 8 AWG | 40 Amps | 30 Amps |

| 6 AWG | 55 Amps | 40 Amps |

Note: Always refer to the NEC table and local code for accurate ampacity ratings based on installation conditions.

what is mtw wire used for?

MTW wire is specifically designed for environments that require flexibility, flame resistance, and resistance to oil and abrasion. Typical applications include:

Control cabinets and panels

Machine tool wiring

Internal wiring of appliances and industrial equipment

Conduit and tray wiring in commercial buildings

Terminal blocks and motor leads

It’s suitable for use in dry and damp locations and is frequently used in automated manufacturing environments.

MTW Wire vs THHN: What’s the Difference?

Both MTW and THHN wires are used for building and equipment wiring, but they serve different purposes:

| Feature | MTW Wire | THHN Wire |

|---|---|---|

| Flexibility | More flexible | Less flexible |

| Environment | Moisture, oil, machine tools | Conduit, dry/wet locations |

| Insulation | PVC | Nylon-jacketed PVC |

| Temperature | 90°C dry / 60°C wet | 90°C dry / 75°C wet |

| Typical Use | Machine tools, panels | Building wire, conduit |

Which to choose? Use MTW wire for flexible, industrial use in control systems. Choose THHN wire for general-purpose building wiring through conduit.

Why Choose MTW Wire from TOT Wire & Cable?

At TOT Wire & Cable, we stock a wide range of MTW wire sizes, colors, and spool lengths to meet your electrical and industrial needs. Our MTW wire is:

UL listed and CSA certified

Available in bulk or cut-to-length

Manufactured for long-term reliability in demanding environments

Need a Quote or More Info?

Looking to buy MTW wire in bulk or learn more about the right size for your application? Contact our team for specifications, lead times, and competitive pricing.