Cross-linked polyethylene, commonly abbreviated as XLPE, has revolutionized the electrical cable industry with its superior performance characteristics and versatility. As one of the most widely used insulation materials in power cables, XLPE Insulated Power Cables offers exceptional electrical, thermal, and mechanical properties that make it ideal for applications ranging from residential wiring to high-voltage transmission systems. This comprehensive guide explores everything you need to know about XLPE, from its fundamental properties to its applications in modern electrical infrastructure.

What is XLPE: Complete Guide to Cross-Linked Polyethylene in Cable Applications

What is XLPE (Cross-Linked Polyethylene)?

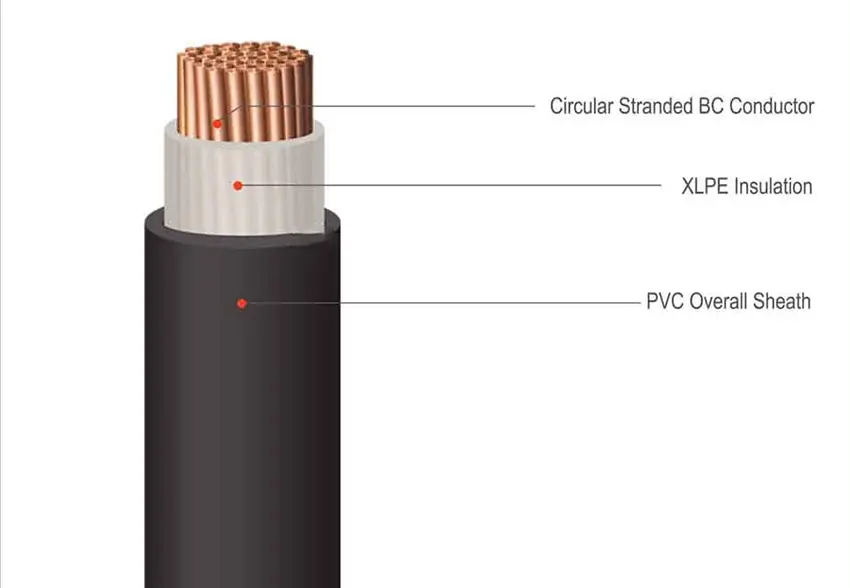

XLPE, or cross-linked polyethylene, is a thermoset polymer created by chemically linking polyethylene molecules through a process called cross-linking. This molecular transformation converts regular thermoplastic polyethylene into a thermoset material with significantly enhanced properties. The cross-linking process creates a three-dimensional network of polymer chains that cannot be re-melted once formed, resulting in superior thermal stability, mechanical strength, and chemical resistance compared to standard polyethylene.

The cross-linking process fundamentally alters the molecular structure of polyethylene, creating covalent bonds between polymer chains. This network structure gives XLPE its distinctive properties that make it particularly valuable in electrical applications where temperature resistance, mechanical durability, and electrical performance are critical.

XLPE Manufacturing Process and Cross-Linking Methods

The production of XLPE involves several sophisticated manufacturing processes, each with its own advantages and applications:

Peroxide Cross-Linking (Chemical Cross-Linking)

The most common method for producing XLPE insulation involves the use of organic peroxides as cross-linking agents. During this process:

- Polyethylene is mixed with peroxide compounds

- The mixture is heated to temperatures between 150°C and 200°C

- Free radicals generated by the peroxide create cross-links between polymer chains

- The resulting material exhibits enhanced thermal and mechanical properties

This method is widely used in cable manufacturing due to its reliability and the consistent quality of the final product.

Silane Cross-Linking (Moisture Cure)

Silane cross-linking utilizes moisture-activated silane compounds:

- Polyethylene is grafted with vinyl silane

- Cross-linking occurs in the presence of moisture and a catalyst

- The process can continue at room temperature over several days

- This method is particularly useful for thin-wall applications and wire insulation

Electron Beam Cross-Linking (Physical Cross-Linking)

This advanced method uses high-energy electron beams:

- No chemical additives are required

- Cross-linking occurs through the bombardment of electrons

- Provides precise control over the degree of cross-linking

- Results in extremely pure XLPE with minimal by-products

UV Cross-Linking

Ultraviolet light cross-linking uses photoinitiators:

- UV radiation activates chemical cross-linking agents

- Suitable for thin films and surface applications

- Offers rapid processing times

- Used primarily in specialized applications

Key Properties of XLPE Materials

XLPE exhibits a unique combination of properties that make it superior to many other insulation materials:

Thermal Properties

- Operating Temperature Range: Typically -40°C to +90°C for continuous operation

- Short-Circuit Temperature: Can withstand temperatures up to 250°C for short durations

- Thermal Stability: Maintains properties across wide temperature ranges

- Low Thermal Expansion: Dimensional stability under temperature variations

Electrical Properties

- Excellent Dielectric Strength: High breakdown voltage resistance

- Low Dielectric Loss: Minimal power loss during transmission

- Low Dielectric Constant: Typically 2.3-2.4 at 50/60 Hz

- High Insulation Resistance: Excellent long-term electrical performance

- Corona Resistance: Superior performance in high-voltage applications

Mechanical Properties

- High Tensile Strength: Superior to thermoplastic polyethylene

- Excellent Flexibility: Maintains flexibility even at low temperatures

- Impact Resistance: Good resistance to mechanical shock

- Abrasion Resistance: Suitable for demanding installation conditions

- Memory Effect: Returns to original shape after deformation

Chemical Properties

- Chemical Resistance: Resistant to acids, bases, and most solvents

- Water Resistance: Extremely low water absorption

- Ozone Resistance: Excellent performance in outdoor applications

- UV Resistance: Good resistance to ultraviolet radiation when properly formulated

XLPE vs Other Insulation Materials

Understanding how XLPE compares to other common insulation materials helps explain its widespread adoption:

| Property | XLPE | PVC | EPDM | Polyethylene |

|---|---|---|---|---|

| Max Operating Temperature | 90°C | 70°C | 90°C | 70°C |

| Flexibility | Excellent | Good | Excellent | Good |

| Chemical Resistance | Excellent | Moderate | Excellent | Good |

| Electrical Properties | Superior | Good | Good | Good |

| Fire Resistance | Good with additives | Good | Moderate | Poor |

| Cost | Moderate | Low | High | Low |

| Environmental Impact | Good | Moderate | Good | Good |

XLPE vs PVC Insulation

While PVC (polyvinyl chloride) has been traditionally used in cable insulation, XLPE offers several advantages:

- Higher temperature rating (90°C vs 70°C)

- Better electrical properties

- No plasticizer migration issues

- Superior chemical resistance

- Better performance in harsh environments

XLPE vs EPDM Rubber

EPDM (ethylene propylene diene monomer) rubber competes with XLPE in some applications:

- XLPE offers better electrical properties

- EPDM provides superior flexibility at very low temperatures

- XLPE has better chemical resistance to hydrocarbons

- Both offer similar temperature ratings

Applications of XLPE in Cable Industry

XLPE's versatility makes it suitable for a wide range of cable applications across various industries:

Power Distribution Cables

XLPE insulated power cables are extensively used in:

- Low Voltage Applications (up to 1kV): Residential and commercial wiring

- Medium Voltage Systems (1kV to 35kV): Industrial distribution networks

- High Voltage Transmission (35kV and above): Utility transmission lines

- Underground Cable Systems: Direct burial and duct installations

- Submarine Power Cables: Offshore wind farms and island connections

Building Wire and Cable

In construction applications, XLPE provides:

- Enhanced fire safety with low-smoke, zero-halogen formulations

- Compliance with building codes and safety standards

- Long-term reliability in concealed installations

- Resistance to environmental stresses

Automotive Wire and Cable

The automotive industry benefits from XLPE's properties:

- High-temperature resistance for engine compartment applications

- Chemical resistance to automotive fluids

- Flexibility for routing through tight spaces

- Durability under vibration and mechanical stress

Industrial and Control Cables

XLPE is used in industrial settings for:

- Motor leads and power supply cables

- Instrumentation and control wiring

- Variable frequency drive (VFD) cables

- Hazardous location applications

Renewable Energy Applications

The growing renewable energy sector relies on XLPE for:

- Solar PV Cables: UV resistance and temperature performance

- Wind Power Cables: Flexibility for turbine applications

- Energy Storage Systems: Battery interconnect cables

- Grid Integration: Power conditioning equipment connections

XLPE Cable Standards and Specifications

XLPE cables must meet various international and national standards:

International Standards

- IEC 60502: Power cables with extruded solid dielectric for voltages up to 30kV

- IEC 60840: Power cables with extruded insulation for voltages above 30kV

- IEC 62067: Single core cables with extruded insulation for voltages above 150kV

North American Standards

- UL 44: Thermoset-insulated wires and cables

- AEIC CS8: Specifications for XLPE-insulated cables

- IEEE 1202: Flame testing of cables for use in cable trays

European Standards

- HD 620: Distribution cables with extruded insulation for voltages up to 3kV

- EN 50618: Solar cables (photovoltaic applications)

- BS 7870: Cables for voltages up to and including 3.8/6.6kV

Advantages of XLPE Insulation

The widespread adoption of XLPE is due to its numerous advantages:

Performance Benefits

- Superior Electrical Properties: Lower dielectric losses and higher breakdown strength

- Enhanced Temperature Rating: Allows higher current carrying capacity

- Mechanical Durability: Excellent resistance to physical damage

- Chemical Stability: Resistant to environmental stresses and chemicals

- Long Service Life: Proven reliability over decades of use

Economic Advantages

- Reduced Cable Size: Higher temperature rating allows smaller conductors

- Lower Installation Costs: Easier handling and installation

- Reduced Maintenance: Long-term reliability reduces replacement needs

- Energy Efficiency: Lower losses improve system efficiency

Environmental Benefits

- Recyclability: Can be recycled through specialized processes

- No Harmful Additives: Free from plasticizers and heavy metals

- Reduced Environmental Impact: Longer service life reduces waste

- Low Smoke Formulations: Available in fire-safe variants

Challenges and Limitations of XLPE

Despite its many advantages, XLPE does have some limitations:

Water Treeing

Water treeing is a degradation phenomenon that can occur in XLPE insulation:

- Microscopic channels form in the presence of moisture and electrical stress

- Can lead to eventual insulation failure if not addressed

- Modern XLPE formulations include tree-retardant additives (TR-XLPE)

- Proper cable design and installation practices minimize this risk

Processing Considerations

- Cross-linking requires specialized manufacturing equipment

- Quality control is critical during the cross-linking process

- Higher processing temperatures compared to thermoplastic materials

- Cannot be reprocessed once cross-linked

Cost Factors

- Initial material cost is higher than standard polyethylene

- Manufacturing processes are more complex and energy-intensive

- Specialized equipment required for production

Future Developments in XLPE Technology

The XLPE industry continues to evolve with new developments:

Advanced Formulations

- Nano-Enhanced XLPE: Incorporation of nanoparticles for improved properties

- Bio-Based XLPE: Development of renewable feedstock-based materials

- High-Temperature XLPE: Materials rated for operation above 90°C

- Enhanced Tree-Resistant Formulations: Further improvements in water tree resistance

Smart Cable Technologies

- Integration of sensing capabilities within XLPE insulation

- Temperature and stress monitoring systems

- Predictive maintenance applications

- IoT-enabled cable health monitoring

Sustainability Initiatives

- Development of more efficient recycling processes

- Reduction of manufacturing energy requirements

- Bio-based cross-linking agents

- Circular economy approaches to XLPE lifecycle management

Quality Testing and Performance Evaluation

XLPE cables undergo rigorous testing to ensure performance and safety:

Electrical Tests

- Dielectric Strength Testing: High-voltage breakdown tests

- Partial Discharge Testing: Detection of insulation defects

- Long-Term Electrical Aging: Extended voltage stress testing

- Lightning Impulse Testing: Transient voltage performance

Thermal Tests

- Thermal Aging: Long-term exposure to elevated temperatures

- Thermal Shock Testing: Rapid temperature cycling

- Heat Deformation Testing: Mechanical stability at high temperatures

Mechanical Tests

- Tensile and Elongation Testing: Mechanical strength evaluation

- Impact Resistance Testing: Ability to withstand mechanical shock

- Bend Testing: Flexibility and crack resistance

- Abrasion Resistance: Durability under mechanical stress

Environmental Tests

- UV Resistance Testing: Long-term outdoor exposure simulation

- Chemical Resistance Testing: Exposure to various chemicals

- Water Absorption Testing: Moisture resistance evaluation

- Ozone Resistance Testing: Performance in oxidizing environments

Installation and Handling Best Practices

Proper installation is crucial for maximizing XLPE cable performance:

Storage and Handling

- Store cables in dry, covered areas away from direct sunlight

- Avoid excessive bending or kinking during transport

- Use proper lifting and handling equipment for heavy cables

- Maintain recommended temperature ranges during installation

Installation Guidelines

- Follow manufacturer's minimum bend radius specifications

- Use appropriate pulling tensions to avoid damage

- Provide adequate support and protection in cable trays

- Ensure proper grounding and bonding practices

Termination and Splicing

- Use compatible accessories designed for XLPE cables

- Follow proper cleaning and preparation procedures

- Apply stress control materials where required

- Ensure moisture sealing in outdoor applications

Conclusion: The Future of XLPE in Electrical Applications

XLPE has established itself as the premier insulation material for modern electrical cables, offering an exceptional combination of electrical, thermal, and mechanical properties. As electrical infrastructure continues to evolve with renewable energy integration, smart grid technologies, and increasing power demands, XLPE's versatility and performance characteristics make it well-positioned to meet future challenges.

From residential building wire to high-voltage transmission cables, XLPE continues to enable safer, more efficient, and more reliable electrical systems. As manufacturing processes improve and new formulations are developed, XLPE will likely maintain its position as the material of choice for demanding electrical applications.

Understanding what XLPE is and its properties helps engineers, technicians, and facility managers make informed decisions about cable selection, ensuring optimal performance, safety, and long-term value in their electrical installations. Whether you're designing a new electrical system or upgrading existing infrastructure, XLPE insulated cables offer proven performance and reliability that will serve your applications for decades to come.

2 comments

Link dewijoker} 09/26/2025

Amazing issues here. I'm very satisfied to look your article. Thanks a lot and I am taking a look forward to contact you. Will you please drop me a mail?

Totcables 09/26/2025

what can I do for you