Selecting the correct wire size for a 60 amp electrical circuit is crucial for safety, code compliance, and optimal performance. Whether you're installing a subpanel, electric car charger, or high-power appliance, this comprehensive guide will help you choose the right wire gauge and understand the installation requirements.

what size wire for 60 amp

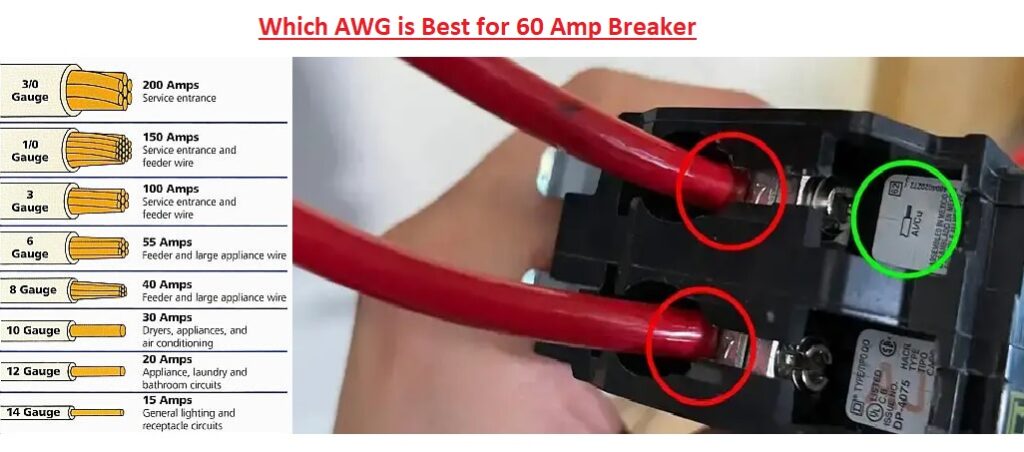

Quick Answer: Wire Sizes for 60 Amp Circuits

For standard 60 amp electrical circuits, you need:

- 6 AWG copper wire for most applications

- 4 AWG aluminum wire for equivalent ampacity

- 4 AWG copper wire for long runs or high-temperature conditions

These sizes apply to typical residential installations with standard temperature ratings and distances up to 100 feet.

Understanding 60 Amp Wire Requirements

The National Electrical Code (NEC) requires that wire ampacity must meet or exceed the circuit breaker rating. For 60 amp circuits, 6 AWG copper wire with an ampacity of 65 amps under standard conditions meets this requirement with a small safety margin.

Key Ampacity Ratings:

- 6 AWG copper: 65 amps

- 4 AWG copper: 85 amps

- 4 AWG aluminum: 65 amps

- 2 AWG aluminum: 90 amps

Common Applications for 60 Amp Circuits

Electric Vehicle Charging Stations

- Level 2 EV chargers (240V, 50-60 amps)

- Tesla Wall Connector and similar units

- Hardwired charging stations

- Future-proofing for faster charging

Subpanels and Electrical Panels

- Garage subpanels for workshop equipment

- Detached building electrical service

- Pool house or shed electrical systems

- Home addition electrical panels

High-Power Appliances

- Electric cooktops and ranges (some models)

- Large electric water heaters

- Electric furnaces and heat pumps

- Commercial-grade equipment

Workshop and Industrial Equipment

- Welding equipment circuits

- Large air compressors

- Industrial machinery

- Kiln and furnace installations

Factors Affecting Wire Size Selection

Distance and Voltage Drop

Wire size may need to increase based on distance:

- Up to 50 feet: 6 AWG copper typically adequate

- 50-100 feet: Consider voltage drop calculations

- 100-200 feet: May require 4 AWG or larger

- Over 200 feet: Professional calculation essential

Temperature Conditions

Ambient temperature affects wire ampacity:

- Hot attics: May require derating to 4 AWG

- Underground installations: Soil temperature considerations

- Bundled cables: Heat buildup requires larger wire

- Cold climates: Generally less impact on sizing

Installation Method

How wire is installed affects ampacity:

- Free air: Full ampacity rating applies

- Conduit with multiple wires: Derating factors apply

- Direct burial: Special cable types required

- Overhead spans: Mechanical strength considerations

Copper vs. Aluminum Wire for 60 Amp Circuits

Copper Wire Advantages

- Higher conductivity: Smaller physical size for same ampacity

- Corrosion resistance: Longer lifespan in most environments

- Easier connections: Standard terminals and connections

- Flexibility: Easier to bend and route

Aluminum Wire Considerations

- Cost savings: Significantly less expensive than copper

- Larger size required: 4 AWG aluminum vs. 6 AWG copper

- Special connections: Requires AL-rated terminals and connectors

- Expansion concerns: Thermal expansion/contraction issues

Wire Types for 60 Amp Installations

THWN-2 Individual Conductors

- Used in conduit systems

- Excellent for underground installations

- High temperature rating (90°C)

- Suitable for wet locations

USE-2 Direct Burial Cable

- Designed for underground installations

- Single conductor cables

- Sunlight resistant

- Moisture and chemical resistant

SER/SEU Service Entrance Cable

- Pre-assembled cable with multiple conductors

- Includes neutral and ground conductors

- Common for subpanel installations

- Available in copper and aluminum

MC Cable (Metal Clad)

- Flexible metal sheathing protection

- Good for exposed installations

- Combines conduit protection with cable flexibility

- Available in various conductor configurations

Installation Requirements and Code Compliance

National Electrical Code (NEC) Standards

- Ampacity requirements: Wire must meet or exceed 60 amps

- Grounding requirements: Proper equipment grounding conductor

- Installation methods: Approved wiring methods and materials

- Protection requirements: Overcurrent protection and disconnects

Local Code Variations

- Permit requirements: Most jurisdictions require permits

- Inspection requirements: Professional inspection typically required

- Installation methods: Local preferences for conduit vs. cable

- Professional licensing: May require licensed electrician

Grounding and Bonding

- Equipment grounding conductor: Must be sized per NEC Table 250.122

- Grounding electrode conductor: For subpanels and service equipment

- Bonding requirements: Proper bonding of metal components

- GFCI protection: Required in specific locations

Calculating Voltage Drop for 60 Amp Circuits

Voltage drop becomes critical for 60 amp circuits, especially over long distances. The NEC recommends keeping voltage drop under 5% for combined feeder and branch circuits.

Voltage Drop Calculation Factors

- Circuit amperage: 60 amps for full load

- Wire resistance: Varies by conductor size and material

- Distance: One-way distance in feet

- Voltage: 120V or 240V depending on application

When to Upsize Wire

Consider larger wire when:

- Distance exceeds 100 feet

- Voltage drop calculations exceed 3%

- Critical equipment requires stable voltage

- Future expansion may increase loads

Professional Installation Considerations

Electrical Permits and Inspections

- Permit applications: Required for most 60 amp installations

- Plan approval: Complex installations may require plan review

- Inspection schedule: Rough-in and final inspections typically required

- Code compliance: Must meet current NEC and local codes

Licensed Electrician Requirements

Many jurisdictions require professional installation for:

- Service panel modifications

- Subpanel installations

- High-voltage circuits (240V)

- Permanent equipment connections

Utility Coordination

- Load calculations: May affect service capacity

- Meter modifications: Some installations require utility involvement

- Service upgrades: May trigger whole-house electrical upgrades

- Interconnection agreements: Especially for EV charging stations

Cost Analysis for 60 Amp Wire Installation

Material Costs

- 6 AWG copper wire: $3-6 per foot

- 4 AWG aluminum wire: $2-4 per foot

- Conduit and fittings: $1-3 per foot additional

- Electrical panel components: $100-300 for breakers and connections

Installation Costs

- Professional installation: $1,500-4,000 typical range

- Permit and inspection fees: $100-500 depending on location

- Trenching and conduit: $5-15 per foot for underground runs

- Equipment costs: Panels, disconnects, and safety equipment

Long-term Value Considerations

- Energy efficiency: Proper wire sizing reduces energy loss

- Safety investment: Prevents fire hazards and electrical problems

- Property value: Professional electrical work adds home value

- Future flexibility: Adequate capacity for system expansion

Safety Considerations and Best Practices

Installation Safety

- Turn off power: Always work with power disconnected

- Proper tools: Use insulated tools and safety equipment

- Code compliance: Follow all applicable electrical codes

- Professional help: Consult electricians for complex installations

Ongoing Maintenance

- Regular inspections: Annual visual inspections recommended

- Connection tightness: Check connections for looseness

- Load monitoring: Ensure circuits aren't overloaded

- Professional servicing: Periodic professional inspections

Common Installation Mistakes to Avoid

Undersized Wire

- Using 8 AWG instead of 6 AWG for 60 amp circuits

- Ignoring voltage drop on long runs

- Not accounting for temperature derating

- Mixing wire sizes in same circuit

Improper Connections

- Using non-rated terminals for aluminum wire

- Inadequate torque on connections

- Mixing copper and aluminum without proper connectors

- Poor grounding and bonding practices

Code Violations

- Skipping required permits and inspections

- Using non-approved installation methods

- Inadequate overcurrent protection

- Missing required safety disconnects

Planning Your 60 Amp Circuit Installation

Load Assessment

- Calculate total load: Determine actual amperage requirements

- Consider future needs: Plan for potential load increases

- Evaluate existing service: Ensure adequate panel capacity

- Check utility requirements: Verify service capacity

Route Planning

- Shortest practical path: Minimize wire length and costs

- Accessibility: Plan for future maintenance access

- Protection from damage: Avoid areas prone to physical damage

- Code compliance: Meet clearance and installation requirements

Equipment Selection

- Panel capacity: Ensure adequate space and capacity

- Breaker selection: Choose appropriate overcurrent protection

- Disconnect requirements: Install required safety disconnects

- Grounding equipment: Proper grounding and bonding components

Troubleshooting 60 Amp Circuit Issues

Voltage Problems

- Low voltage: Check for loose connections or undersized wire

- Voltage fluctuations: May indicate overloaded circuit or poor connections

- Unbalanced loads: Check 240V circuit balance

- Voltage drop: Measure voltage at source and load

Overcurrent Protection Issues

- Breaker trips immediately: Likely short circuit or ground fault

- Frequent tripping: Circuit may be overloaded

- Breaker won't reset: Serious fault requiring immediate attention

- Nuisance tripping: May indicate arc fault or ground fault issues

Future-Proofing Your 60 Amp Installation

Technology Considerations

- EV charging evolution: Faster charging may require upgrades

- Smart home integration: Plan for monitoring and control systems

- Energy storage: Battery backup systems may need high-amperage circuits

- Renewable energy: Solar systems may require high-capacity circuits

Expansion Planning

- Additional circuits: Plan conduit capacity for future wires

- Panel space: Ensure adequate space for future breakers

- Service capacity: Consider whole-house electrical loads

- Infrastructure: Plan for future electrical infrastructure needs

Environmental and Efficiency Considerations

Energy Efficiency

- Proper wire sizing: Reduces energy losses

- Quality connections: Minimize resistance and heat generation

- Load balancing: Optimize electrical system efficiency

- Power factor: Consider power factor correction for motor loads

Environmental Impact

- Material selection: Consider recyclability and environmental impact

- Energy conservation: Efficient electrical systems reduce overall consumption

- Renewable integration: Plan for future renewable energy connections

- Sustainable practices: Choose environmentally responsible installation methods

Conclusion

Selecting the right wire size for 60 amp circuits requires careful consideration of ampacity requirements, installation conditions, and code compliance. While 6 AWG copper wire meets the basic requirements for most applications, factors like distance, temperature, and installation method may require larger wire sizes.

Professional installation is highly recommended for 60 amp circuits due to safety concerns and code compliance requirements. The investment in proper wire sizing and installation ensures safe, reliable electrical service and protects your property and family.

Always consult with licensed electricians and local authorities having jurisdiction to ensure your installation meets all applicable codes and safety standards. Proper planning and professional installation of 60 amp circuits provides the foundation for safe, efficient electrical systems that will serve your needs for years to come.

Frequently Asked Questions

Q: Can I use 8 AWG wire for a 60 amp circuit? A: No, 8 AWG wire is only rated for 50 amps maximum. You must use at least 6 AWG copper or 4 AWG aluminum for 60 amp circuits.

Q: How far can I run 6 AWG wire for a 60 amp circuit? A: For most applications, 6 AWG copper can run up to 100 feet without significant voltage drop issues. Longer runs may require 4 AWG wire.

Q: Do I need a permit for installing a 60 amp circuit? A: Most jurisdictions require permits for 60 amp circuit installations, especially for subpanels or high-power equipment. Check with your local building department.

Q: Can I install a 60 amp circuit myself? A: While some jurisdictions allow homeowner installation, 60 amp circuits involve high-power electrical work that's best left to licensed electricians for safety and code compliance.

Q: What's the difference between 60 amp and 50 amp wire requirements? A: 60 amp circuits require 6 AWG copper wire, while 50 amp circuits can use 8 AWG copper wire. The larger wire provides the additional current capacity and safety margin required for 60 amp loads.

1 comment

Tips outreach untuk backlink 08/07/2025

I think this is among the most significant information for me. And i am glad reading your article. But want to remark on few general things, The site style is ideal, the articles is really nice : D. Good job, cheers