When it comes to choosing welding cables, one of the most important decisions is selecting the right conductor material: copper or aluminum. While both metals are used in electrical applications, copper is widely considered the better choice for welding cables — and for good reason.

In this article, we’ll explain why copper is better than aluminum for welding cables, covering conductivity, flexibility, durability, safety, and more.

why is copper better than aluminum for welding cables

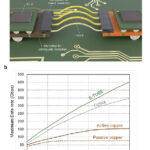

1. Superior Electrical Conductivity

Copper has a much higher electrical conductivity than aluminum. In fact, copper conducts electricity about 60% better than aluminum. This means a copper welding cable can carry more current over the same cross-sectional area — or the same current through a smaller-sized cable.

✅ What this means for welding:

Better conductivity results in more stable arc performance, less power loss, and lower resistance heating in the cable.

2. Greater Flexibility

Welding often requires frequent cable movement, coiling, and bending. Copper wires are more flexible than aluminum because copper is a denser and more ductile metal.

✅ Why this matters:

Flexible welding cables are easier to handle, reduce operator fatigue, and last longer in rugged environments.

3. Higher Mechanical Strength

Copper has better mechanical strength compared to aluminum, which means:

It’s less likely to break under stress

It’s more resistant to fatigue cracking over time

✅ For welding applications, where cables are regularly dragged, twisted, and exposed to impact, copper simply holds up better.

4. Better Corrosion Resistance in Harsh Environments

While aluminum oxidizes easily, forming a non-conductive layer, copper resists corrosion more effectively — especially in humid, dirty, or chemically active environments often found in industrial and construction sites.

✅ This leads to better long-term performance and fewer safety risks caused by deteriorated conductors.

5. Long-Term Cost Efficiency

Although copper welding cables cost more upfront than aluminum alternatives, the longer service life, better performance, and lower maintenance costs make copper a more economical choice in the long run.

When Is Aluminum Used?

Aluminum is lighter and cheaper than copper. It may be used in large, fixed installations where weight and flexibility aren’t important, and where cost is a major factor.

However, for welding applications, where flexibility, conductivity, and mechanical strength are critical, copper remains the superior choice.

Conclusion: Choose Copper for Reliable Welding Performance

Why is copper better than aluminum for welding cables?

Because it delivers higher conductivity, greater flexibility, better strength, and improved durability — all essential for safe and efficient welding work.

If you're looking for high-quality copper welding cables, we can help.

Get High-Quality Copper Welding Cables

At TOT Wire & Cable, we offer:

100% copper welding cables

Flexible and durable rubber insulation

Multiple gauge sizes (from 6 AWG to 4/0 AWG) for every welding need