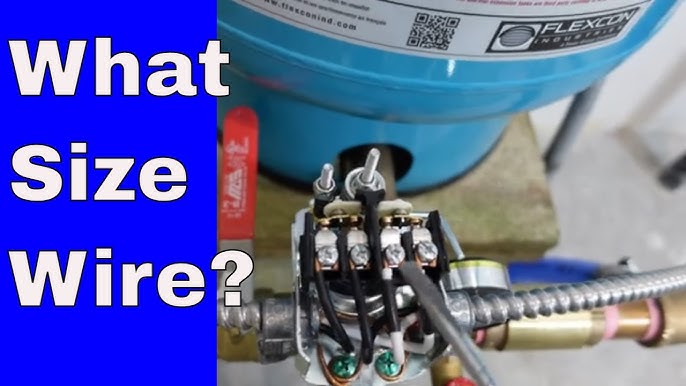

Choosing the correct wire size for a well pump is critical for efficient pump performance, safety, and long-term reliability. Undersized wires can lead to voltage drop, reduced pump efficiency, overheating, and even system failure. In this guide, we'll explain how to select the proper wire size based on pump horsepower, voltage, distance, and installation type.

Wire Size for Well Pump

Why Wire Size Matters for Well Pumps

Well pumps operate deep underground and often over long cable runs. Choosing the right wire size ensures:

Adequate voltage reaches the pump motor

Reduced energy loss due to resistance

Minimized risk of overheating and fire

Compliance with National Electrical Code (NEC) standards

Key Factors That Affect Wire Size Selection

To determine the correct wire size, you need to consider the following:

1. Pump Motor Horsepower (HP)

The higher the HP, the more current the motor draws. Common well pump sizes include:

1/2 HP

3/4 HP

1 HP

1.5 HP

2 HP

2. Voltage Supply

Most residential well pumps run on either:

115V (short runs, smaller pumps)

230V (more efficient for longer distances or higher HP)

3. Distance from Power Source

Longer wire runs require larger wires to minimize voltage drop. Always measure the total length of wire, not just the depth of the well.

4. Wire Type

Use wire rated for direct burial or submersible pump cable—typically THWN, TWU, or UF cable, depending on the setup.

Recommended Wire Sizes for Well Pumps (230V Systems)

| HP Rating | Max Distance (ft) | Wire Gauge (AWG) |

|---|---|---|

| 1/2 HP | Up to 250 ft | 14 AWG |

| 251–400 ft | 12 AWG | |

| 3/4 HP | Up to 150 ft | 12 AWG |

| 151–300 ft | 10 AWG | |

| 1 HP | Up to 250 ft | 10 AWG |

| 251–400 ft | 8 AWG | |

| 1.5 HP | Up to 200 ft | 8 AWG |

| 201–350 ft | 6 AWG | |

| 2 HP | Up to 300 ft | 6 AWG |

| 301–500 ft | 4 AWG |

Note: For 115V systems, wire sizes must be larger due to higher current draw. Always refer to NEC code and pump manufacturer guidelines.

Submersible Pump Cable Types

Well pump wire is usually grouped in flat or round jacketed cables, labeled as 2-wire (with ground) or 3-wire (with ground) configurations. The control box location also affects cable choice:

2-Wire Pumps: Controls are built into the motor; simpler wiring.

3-Wire Pumps: Use external control boxes; easier to service.

How to Measure Wire Run Correctly

Total wire length = distance from electrical panel to pressure switch + switch to well head + depth of pump. Always include horizontal + vertical distances for accurate calculations.

Installation and Safety Tips

Always turn off power before installation.

Use waterproof splices and heat shrink tubing for submersible connections.

Secure wires with cable guards inside the well casing.

Ensure all equipment is grounded properly to prevent electrical shock.

Conclusion

Choosing the right wire size for your well pump is essential to avoid system failures and maximize efficiency. Always base your selection on horsepower, voltage, distance, and proper wire type. When in doubt, go one size larger than required to accommodate future upgrades or minor errors in distance estimates.

Need help choosing the right cable? Contact our experts for assistance or browse our full range of submersible pump cables.

3 comments

Build backlinks for your website seo 10/18/2025

I'd forever want to be update on new blog posts on this website , saved to my bookmarks! .

Donna Rose 11/11/2025

I have a buried tank, (maybe 6' deep) and an uphill run between pump and wellhouse of about 500'. What size wire do I need?

Totcables 11/12/2025

I need a bit more information to give you the right wire size: What voltage is the pump? (120V or 240V - most deep well pumps are 240V) What's the pump's horsepower or amperage? (This should be on the pump nameplate - common sizes are 1/2 HP, 3/4 HP, 1 HP, 1.5 HP, etc.) What's the starting amperage (LRA - Locked Rotor Amps)? (Also on the nameplate - this is important for voltage drop calculations) For a 500-foot run, voltage drop is a serious concern. With that distance, you'll likely need to go at least one or two wire sizes larger than the minimum to keep voltage drop under 3% (which is important for motor longevity and starting capability). As a rough guide for 240V pumps at 500 feet: 1/2 HP: Likely 8 AWG minimum, possibly 6 AWG 3/4 HP: 6 AWG minimum, possibly 4 AWG 1 HP: 4 AWG minimum, possibly 2 AWG 1.5 HP: 2 AWG or larger But I can give you a precise answer once I know the voltage and amperage. Also, is this going to be buried direct burial wire, or run in conduit?