Our 25mm² 3 Core Steel Wire Armoured (SWA) Cable is a highly durable and reliable solution for mains electricity supply in low voltage installation systems. Constructed with XLPE insulation, robust Steel Wire Armour (SWA), and a protective PVC oversweath, this cable is designed to provide mechanical protection and withstand various environmental conditions. Engineered for a rated voltage of 0.6/1kV, it is suitable for both internal and external fixed wiring applications.

Applications

This 25mm² 3 Core SWA Armoured Cable is commonly used for electricity supply in low voltage systems across diverse environments:

- Underground Laying: Suitable for direct burial thanks to its robust steel wire armouring, providing enhanced protection from external mechanical damage.

- Power Networks: Essential for general power distribution within low voltage installations.

- Incoming Mains Supply: Often used as an incoming mains cable for residential, commercial, and industrial properties.

- Indoor & Outdoor Installations: Versatile for use in buildings, industrial plants, and various external applications.

- Cable Ducts: Ideal for installation within conduits and cable ducts.

- Power and Switching Stations: Reliable for critical infrastructure.

- Local Energy Distributions: Key for connecting local power points.

- Industrial Plants: Durable for demanding industrial environments where mechanical protection is crucial.

The XLPE insulation offers excellent resistance to various fluids and chemicals, good heat stability, and is UV resistant, further enhancing the cable's longevity and reliability.

Standards Compliance

Our 25mm² 3 Core SWA Armoured Cables are manufactured and tested to comply with or exceed the requirements of the following international and British standards:

- BS 5467: Electric cables. Thermosetting insulated, armoured cables for voltages of 600/1000 V and 1900/3300 V.

- IEC/EN 60502-1: Power cables with extruded insulation and their accessories for rated voltages from 1kV (Um=1.2kV) up to 35kV (Um=40.5kV) - Part 1: Cables for rated voltages of 1 kV (Um=1.2kV) and 3 kV (Um=3.6kV).

- IEC/EN 60228: Conductors of insulated cables.

- Flame Retardancy: Compliant with IEC/EN 60332-1-2 (single vertical insulated wire or cable).

Construction Details

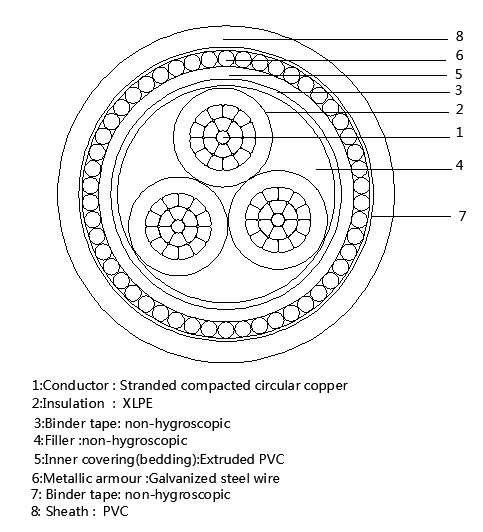

The cable's layered construction ensures high performance, durability, and safety:

- Conductors: Plain circular, compacted, or shaped stranded copper or aluminium conductor (depending on selection), conforming to IEC 60228 Class 2.

- Conductor Shapes: RE (circular solid), CC (compacted circular stranded), SM (sector shaped stranded).

- Insulation: Cross-linked polyethylene (XLPE), designed for a 90°C rated temperature, offering superior electrical properties and high temperature resistance.

- Colour Identification (3 Cores): Typically Red, Yellow, Blue.

- Assembly / Inner Sheath (Bedding): The three insulated conductors are laid-up together with non-hygroscopic fillers (if required) and then bedded with an extruded layer of PVC.

- Armour: Galvanized Steel Wire Armour (SWA) is applied helically over the bedding, providing robust protection against mechanical stress and impact.

- Sheath: An outer layer of Extruded PVC Type ST2 as per IEC 60502-1 or Type 9 as per BS 6346/5467.

Customization Options & Fire Performance

We offer various customization options for the outer sheath to meet specific project requirements:

- Special PVC Sheathing:

- Fire Retardant PVC

- Anti-Termite PVC

- Anti-Rodent PVC

- Sunlight Resistant PVC

- Oil Resistant PVC

- Alternative Sheathing Materials:

- LLDPE (Linear Low-Density Polyethylene)

- MDPE (Medium-Density Polyethylene)

- HDPE (High-Density Polyethylene)

- LSZH (Low Smoke Zero Halogen): Cables can be supplied with LSZH material, complying with standards like IEC 60502-1, BS 7211, BS 6724, or other equivalent standards, to minimize smoke and corrosive gas emission in fire conditions.

- Enhanced Fire Performance: Cables can be supplied with special flame-retardant PVC outer sheaths to comply with the flame test requirements for bunched cables:

- IEC 60332-3-22 (Category A)

- IEC 60332-3-23 (Category B)

- IEC 60332-3-24 (Category C)

Technical Data (25mm² 3 Core SWA)

- Voltage: 600/1000V

- Operating Temperature: Maximum 90°C

- Minimum Bending Temperature: 0°C

- Maximum Short-Circuit Temperature: 250°C (for a maximum duration of 5 seconds)

- Minimum Bending Radius: 20 × cable diameter (for armoured cables)

Contact Us

For inquiries, custom orders, or more detailed technical information on our 25mm² 3 Core Steel Wire Armoured (SWA) Cables, please feel free to reach out.