The XLPE Insulated 3+2 Cores Copper Cable (3×240+2×120mm²) is a low-voltage power cable designed for applications requiring both power distribution and protective grounding. With three phase conductors and two additional conductors (commonly used as protective earth or auxiliary lines), this cable ensures safe, efficient power delivery in industrial and infrastructure settings.

It is manufactured in accordance with IEC 60502-1 and IEC 60228, suitable for fixed installations in indoor and outdoor environments, including cable ducts, trays, direct burial, and industrial power networks.

Applications

Power supply in low-voltage distribution networks (600/1000V)

Industrial facilities requiring high-capacity power transmission with grounding

Utility and infrastructure projects needing large cross-section copper cores

Outdoor installations where robust mechanical and thermal performance is required

Standards

IEC 60228 – Conductors of insulated cables

IEC 60502-1 – Power cables with extruded insulation and their accessories for rated voltages up to 1 kV and 3 kV

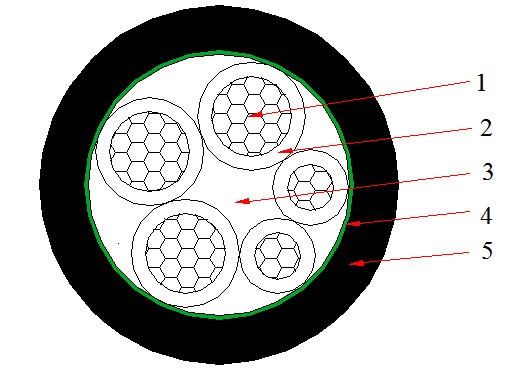

CONSTRUCTION :

XLPE 3X240+2X120mm2 Copper Cable Construction

1. Conductor: Copper , Class 2: stranded conductor

2. Insulation: Cross-linked polyethylene XLPE

3. Filler: Non-hygroscopic material

4. Binder tape: Non-hygroscopic material

5. Outer sheath: Polyvinyl chloride PVC

XLPE 3+2 Cores Cable Construction

Technical Parameters

| Item | Specification |

|---|---|

| Cable Type | CU / XLPE / PVC |

| Rated Voltage (U₀/U) | 600/1000 V |

| Number of Cores | 3 + 2 |

| Phase Conductor Cross-Section | 3 × 240 mm² |

| Earth/Auxiliary Conductor Cross-Section | 2 × 120 mm² |

| Phase Conductor Stranding | 48 wires |

| Earth Conductor Stranding | 24 wires |

| Insulation Thickness (Phase) | 1.7 mm |

| Insulation Thickness (Earth) | 1.2 mm |

| Outer Sheath Thickness | 2.8 mm |

| Overall Diameter | Approx. 56.1 mm |

| Approximate Cable Weight | 8500 kg/km |

| DC Resistance at 20°C (Phase) | 0.0754 Ω/km |

| DC Resistance at 20°C (Earth) | 0.153 Ω/km |

| Current-Carrying Capacity in Air | 480 Amps |

| Current-Carrying Capacity in Ground | 500 Amps |

| Test Voltage | 3.5 kV for 5 minutes |

| Operating Temperature Range | -15°C to +90°C |

| Max. Short-Circuit Temperature | 250°C (5 seconds) |

Advantages

High ampacity with minimal power loss

Excellent thermal and mechanical properties

Resistant to moisture, corrosion, and chemical attack

Long service life under harsh conditions

Ideal for installations requiring robust grounding or auxiliary cores