Three Core 6/10kV Medium Voltage Unarmored Cables with XLPE (Cross-Linked Polyethylene) insulation are engineered for high-performance electricity transmission and distribution applications. These cables excel in medium voltage networks due to their superior electrical and physical properties, offering exceptional reliability while maintaining simplicity in construction, lightweight design, and installation convenience. The XLPE insulation system provides outstanding electrical, thermal, mechanical, and chemical corrosion resistance properties.

Standards Compliance

- Chinese Standard: GB/T 12706-2008

- International Standards: IEC 60502, IEC 60228, IEC 60332

- British Standards: BS 5467, BS 6622

- Indian Standards: IS 1554, IS 7098

- American Standard: ICEA S-66-524

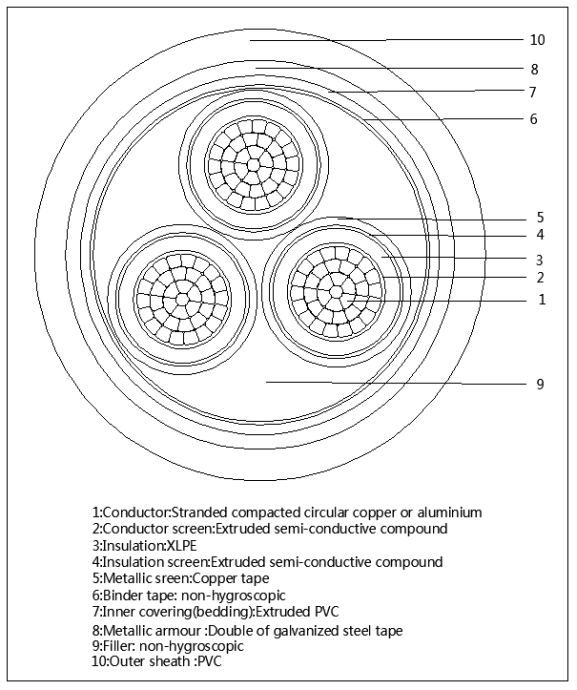

CONSTRUCTION :

Three Core Medium Voltage Unarmored Cable Construction

Conductor

- Material: Plain annealed stranded compacted circular copper or aluminum conductor

- Standard: IEC 60228 Class 2 compliant

- Configuration: Compacted circular stranding for optimal current carrying capacity

Conductor Screen

- Material: Extruded semi-conductive compound

- Function: Provides uniform electric field distribution around the conductor

Insulation System

- Material: XLPE (Cross-Linked Polyethylene)

- Temperature Rating: 90°C continuous operation

- Properties: Excellent dielectric strength, thermal stability, and moisture resistance

Insulation Screen

- Material: Extruded semi-conductive compound

- Function: Controls electric field stress at the insulation outer surface

Metallic Screen

- Options:

- Copper tape screen

- Concentric layer of copper wires

- Function: Provides electromagnetic shielding and fault current path

Core Identification

- Standard Colors: Red, Yellow, Blue identification tapes

- Location: Applied between insulation screen and metallic screen

- Customization: Color coding can be modified per customer requirements

Cable Assembly

- Configuration: Three screened cores laid up together

- Filler: Non-hygroscopic material compatible with insulation (when necessary)

- Inner Coverage: Protected with intermediate layer for enhanced integrity

Outer Sheath Options

- PVC Type ST2: Compliant with IEC 60502 standard

- Polyethylene (PE): Enhanced chemical resistance

- LSZH (Low Smoke Zero Halogen): Fire-safe applications