CVVS Cable is a shielded PVC control cable designed for use in control circuits, station automation systems, and supervisory electrical equipment. With a copper tape shield and durable PVC insulation and sheath, CVVS cables are built for environments where signal integrity, durability, and resistance to interference are essential.

This cable is suitable for indoor and outdoor installation, in wet or dry locations, and can be laid in conduit, duct, trench, or cable tray systems. It fully complies with KS C IEC 60502-1, ensuring safe and reliable performance under a rated voltage of 0.6/1kV.

CVVS Control Cable Application

CVVS control cable is widely used for supervisory electrical equipment and station control circuits. It is suitable for both indoor and outdoor installations, and performs reliably in wet or dry environments. This cable can be installed in conduits, ducts, trenches, and cable trays, making it a versatile choice for industrial and infrastructure projects.

CVVS Control Cable Standard

Manufactured in accordance with KS C IEC 60502-1 standards.

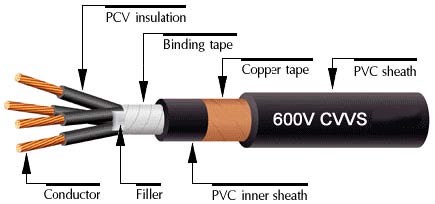

CVVS Control Cable Construction

-

Conductor: Concentric stranded copper wire for excellent conductivity and mechanical strength

-

Insulation: High-quality black PVC insulation

-

Core Identification: White printed numbers on black insulation for easy identification

-

Filler: Filled with suitable material to maintain cable shape and stability

-

Binding Tape: Wrapped with suitable binding tape for compact structure

-

Inner Sheath: Black PVC inner sheath for added protection

-

Shielding: Shielded with annealed copper tape to reduce electromagnetic interference

-

Outer Sheath: Durable black PVC outer sheath for long-term performance in harsh conditions

CVVS Control Cable Construction

Cable Type

| Symbol | MAX. Operating Temperature of Conductor (°C) |

Insulation Materials | Sheath Materials | Application |

| CVV | 60 | PVC | PVC | General use |

| CEV | 75 | Polyethylene | PVC | |

| CCV | 90 | Crosslinked Polyethylene |

PVC | |

| CEE | 75 | Polyethylene | Polyethylene (Black) | Chemical resistance |

| CCE | 90 | Crosslinked Polyethylene | Polyethylene (Black) |

Shield types and symbols

| Shield Type | Symbol | Remarks |

| Annealed copper tape | -S | Annealed copper tape is wrapped around cores. |

| Aluminum laminated plastic tape | -SLA | Applied for grounding through drain wire. |

| Annealed copper wire braid | -SB | Shield is formed by braided copper wire. |

| An

nealed copper tape and steel tape |

-SCF | Annealed copper tape and steel tape are wrapped around cores. |

FAQ: Frequently Asked Questions

Q: What's the difference between CVV and CVVS Cable?

A: CVVS Cable includes a copper tape shield for EMI protection, making it ideal for control circuits in high-interference environments, whereas CVV is unshielded.

Q: Can CVVS cable be used outdoors?

A: Yes, the black PVC sheath is UV-resistant and waterproof, suitable for both indoor and outdoor applications.

Q: Is CVVS suitable for underground installation?

A: Yes, it can be laid in ducts or trenches if properly protected, though armored versions may be preferable for direct burial.

Why Choose CVVS Cable?

Excellent mechanical and electrical performance

Designed for control systems, especially where shielding is required

Reliable in industrial and utility applications

Flexible design for easy installation in tight or complex routes