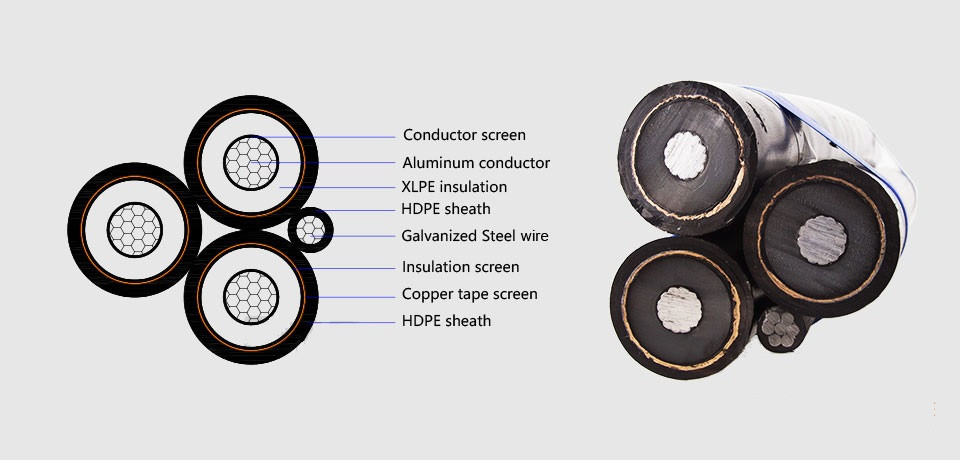

This is a medium-voltage (MV) Aerial Bundled Cable (ABC) designed for overhead power distribution, built to the AS/NZS 3599.1 standard. The cable features a screened design for higher voltage applications, with three insulated cores bundled around a galvanized steel support wire. The construction is denoted by its materials: AL (aluminum conductor), XLPE (insulation), CWS (copper wire screen), and HDPE (sheath).

Key Specifications & Construction

- Voltage: 6.35/11kV

- Conductor: Compacted stranded hard-drawn aluminum (Class 2).

- Conductor Screen: An extruded semi-conductive layer.

- Insulation: Natural cross-linked polyethylene (XLPE).

- Insulation Screen: An extruded semi-conductive layer.

- Metallic Screen: Copper wire screen.

- Sheath: High-density polyethylene (HDPE).

- Support Conductor: Galvanized steel wires.

- Assembly: Three XLPE-insulated and screened cores are bundled in a right-hand lay around the galvanized steel support conductor.

Applications and Technical Data

This cable is used for medium-voltage overhead distribution in applications like street lighting, outdoor lighting, and temporary construction services. It is suitable for a maximum conductor temperature of C.

- Normal Operating Temperature: C

- Emergency Overload Temperature: C

- Short Circuit Temperature: C

MV ABC Aerial Bundled Cables to (AL/XLPE /CWS/HDPE) Parameter

| Number of Cores x Nominal Cross Section | Nominal Conductor Diameter | Nominal Insulation Thickness | Nominal Insulation Screen Thickness | Copper Wire Screen Stranding | Nominal Sheath Thickness | Galvanized Steel Wire Stranding | Nominal Overall Diameter | Weight | Continuous current rating, A | ||

| Still air | 1m/s wind | 2m/s wind | |||||||||

| mm^2 | mm | mm | mm | No/mm | mm | No/mm | mm | kg/km | A | A | A |

| Light duty screen | |||||||||||

| 3x35 | 6.9 | 3.4 | 0.8 | 25/0.85 | 1.8 | 7/2.00 | 54.1 | 1820 | 99 | 140 | 165 |

| 3x35 | 6.9 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 58.1 | 2130 | 100 | 145 | 165 |

| 3x50 | 8.1 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 60.4 | 2300 | 120 | 170 | 200 |

| 3x70 | 9.7 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 63.6 | 2570 | 150 | 215 | 250 |

| 3x95 | 11.4 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 67 | 2900 | 180 | 260 | 305 |

| 3x120 | 12.8 | 3.4 | 0.8 | 25/0.85 | 1.8 | 19/2.00 | 69.8 | 3190 | 205 | 300 | 355 |

| 3x150 | 14.2 | 3.4 | 0.8 | 25/0.85 | 1.9 | 19/2.00 | 73 | 3530 | 235 | 340 | 400 |

| 3x185 | 15.7 | 3.4 | 0.8 | 25/0.85 | 1.9 | 19/2.00 | 76 | 3890 | 265 | 390 | 460 |

| Heavy duty screen | |||||||||||

| 3x35 | 6.9 | 3.4 | 0.8 | 40/0.85 | 1.8 | 7/2.00 | 54.1 | 2050 | 99 | 140 | 165 |

| 3x35 | 6.9 | 3.4 | 0.8 | 40/0.85 | 1.8 | 19/2.00 | 58.1 | 2360 | 100 | 145 | 165 |

| 3x50 | 8.1 | 3.4 | 0.8 | 23/1.35 | 1.8 | 19/2.00 | 62.4 | 2820 | 120 | 175 | 200 |

| 3x70 | 9.7 | 3.4 | 0.8 | 32/1.35 | 1.8 | 19/2.00 | 65.6 | 3440 | 150 | 215 | 250 |

| 3x95 | 11.4 | 3.4 | 0.8 | 39/1.35 | 1.8 | 19/2.00 | 69 | 4030 | 180 | 260 | 305 |

| 3x120 | 12.8 | 3.4 | 0.8 | 39/1.35 | 1.8 | 19/2.00 | 71.8 | 4320 | 205 | 300 | 355 |

| 3x150 | 14.2 | 3.4 | 0.8 | 39/1.35 | 1.9 | 19/2.00 | 75 | 4670 | 230 | 340 | 400 |

| 3x185 | 15.7 | 3.4 | 0.8 | 39/1.35 | 1.9 | 19/2.00 | 78 | 5020 | 265 | 390 | 460 |