All Aluminum Alloy Conductors (AAAC), manufactured to BS EN 50183 standard, represent a superior choice for overhead power transmission and distribution. These conductors are crafted from high-strength aluminum-magnesium-silicon alloys, offering an exceptional balance of mechanical properties and electrical performance. Designed for applications requiring high strength-to-weight ratios and excellent sag characteristics, AAAC conductors provide a reliable and efficient solution for modern electrical networks.

Standards:

BS EN 50183

Key Features

- Superior Strength-to-Weight Ratio: Utilizes high-strength aluminum alloy (e.g., 6201-T81 or 6101) to achieve excellent mechanical support with reduced weight compared to other conductor types.

- Enhanced Electrical Properties: Offers good conductivity, often with lower power losses than equivalent ACSR conductors by eliminating the inductive effect of a steel core.

- Excellent Corrosion Resistance: Inherently resistant to corrosion, making them ideal for use in various environments, including coastal areas where steel-cored conductors might face galvanic corrosion issues.

- Improved Sag Characteristics: Designed to provide good sag performance, allowing for longer spans and reduced pole requirements in overhead lines.

- Durability and Reliability: The robust construction and material properties ensure a long service life with minimal maintenance.

- Flexibility: Stranded construction provides a degree of flexibility for ease of installation, particularly in overhead applications.

- Interchangeability: Often have similar outside diameters to standard ACSR conductors, allowing for the interchangeability of fittings.

Application

AAAC conductors are primarily designed as bare overhead conductors for a wide range of electrical distribution and transmission applications. Their advantages make them particularly suitable for:

- Overhead Power Transmission and Distribution Lines: Used as main conductors for primary and secondary distribution.

- Long Span Installations: Ideal for lines crossing basins, rivers, valleys, or other areas with special geographical features due to their strength and sag characteristics.

- Coastal Regions: Highly favored in environments prone to corrosion, such as near ocean coastlines, where the all-aluminum alloy construction prevents issues seen with steel-reinforced conductors.

- Urban and Rural Networks: Suitable for both urban areas with frequent supports and rural distributions where longer spans are beneficial.

- High Voltage Applications: While bare conductors don't have a specific voltage rating, AAAC can be used effectively across various voltage levels, including those requiring robust mechanical performance.

Standards

Our AAAC - All Aluminum Alloy Conductors are manufactured and tested in strict compliance with leading international standards, including:

- BS EN 50183: Conductors for overhead lines – Aluminium-magnesium-silicon alloy wires.

- GB/T: National Standard of China

- ASTM: American Society for Testing and Materials (e.g., ASTM B399 for AAAC)

- CSA: Canadian Standards Association

- BS: British Standards (e.g., BS 3242 for AAAC)

- DIN: German Institute for Standardization (e.g., DIN 48201)

- IEC: International Electrotechnical Commission (e.g., IEC 61089)

- NF: French National Standard

Construction

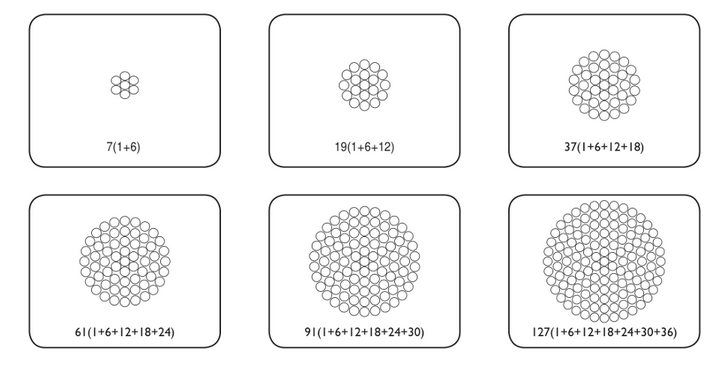

AAAC conductors are concentrically stranded, composed of multiple wires made from high-strength aluminum-magnesium-silicon alloy. The number of wires can vary, commonly including: 7, 19, 37, 61, 91.

All Aluminum Alloy construction

- Conductor Material: Aluminum Alloy

- Insulation Material: Bare (No insulation)

- Sheath Material: Bare (No sheath/jacket)

- Material Shape: Round Wire

- Conductor Type: Stranded

Technical Parameters

Related Voltage:

- 0.6/1kV

- 8.7/15kV

- 12/20kV

- 21/35kV

- 26/35kV

Operating Temperature: While operating temperature can vary based on installation and environmental factors, AAAC is designed for continuous operation at temperatures up to with good sag characteristics.

Quality and Certification

We are committed to delivering high-quality AAAC conductors. Our manufacturing processes and products are certified by:

- ISO9001-2008: Quality Management System

- ISO14001-2004: Environmental Management System

- CCC: China Compulsory Certificate

- SGS, BV: Third-party inspection and certification.

Packaging

Our AAAC conductors are available in various packaging options to suit your specific project requirements:

- Wooden Drum

- Steel Drum

- Customized packaging as per your requirement.

Advantages

Choosing our AAAC - All Aluminum Alloy Conductors provides numerous benefits:

- High Quality: Manufactured to stringent international standards, ensuring reliability and performance.

- Competitive Price: Offering excellent value without compromising on quality.

- Excellent Service: Dedicated support from inquiry to delivery.

For more detailed specifications, custom solutions, or to request a quote, please contact us.