AAAC (All Aluminum Alloy Conductor) is a high-strength, corrosion-resistant bare overhead conductor made entirely of aluminum alloy strands. Designed according to ASTM B399, AAAC is widely used in power transmission and distribution lines, especially where corrosion resistance, high tensile strength, and lightweight construction are critical. It provides an ideal alternative to ACSR, particularly in coastal and marine environments, thanks to its enhanced durability and long-term performance.

Application

AAAC conductors are used as bare overhead conductors for primary and secondary distribution, offering a superior strength-to-weight ratio and good sag characteristics. Common applications include:

-

Overhead distribution and transmission lines in coastal areas, where steel core ACSR conductors are prone to corrosion.

-

Replacement of single-layer ACSR conductors to reduce power losses in overhead systems. Using AAAC instead of ACSR can reduce construction costs by 5–8%.

-

Projects requiring high mechanical strength, yet demanding a conductor lighter than ACSR, such as long-span line crossings or difficult terrain.

Features & Benefits

-

✅ Corrosion Resistance: Ideal for installations in saline or humid environments

-

✅ High Strength-to-Weight Ratio: Supports longer spans with less sag

-

✅ Lower Power Loss: Compared to ACSR, AAAC has reduced power loss due to lower resistance

-

✅ Cost-Effective: Potential savings in material and construction costs

-

✅ Lightweight: Easier to install and handle than steel-reinforced options

-

✅ Reduced Maintenance: Longer service life and minimal corrosion-related failures

Standards

-

ASTM B399 – Standard Specification for Concentric-Lay-Stranded, Aluminum-Alloy 6201-T81 Conductors

Other applicable standards can be met upon request (e.g., IEC, BS).

Construction

-

Conductor: 100% Aluminum Alloy 6201-T81

-

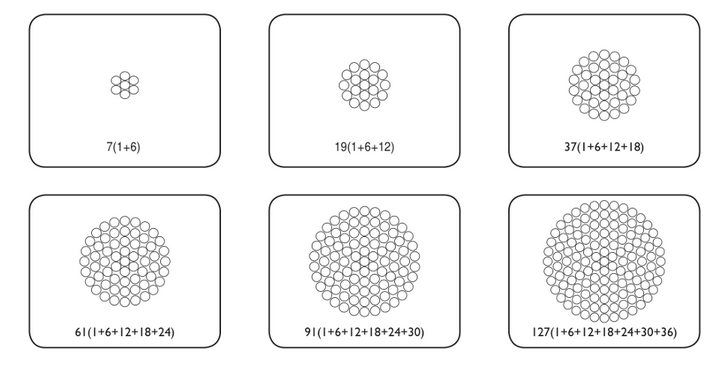

Stranding: Concentric-lay-stranded construction, similar in appearance to AAC or ACSR, but made entirely from aluminum alloy wires

-

Core: No steel core, uniform aluminum alloy strands throughout

All Aluminum Alloy construction

Typical Uses

-

Medium and high-voltage overhead lines

-

Transmission and distribution networks in marine, coastal, and industrial zones

-

Utility line upgrades and system efficiency improvements

-

Rural electrification or areas requiring corrosion-resistant materials

For specifications, datasheets, or a quotation on AAAC ASTM B399 conductors, contact our team — we supply reliable, cost-effective solutions for power transmission projects worldwide.