All Aluminum Alloy Conductors (AAAC), meticulously manufactured to comply with the NFC 34 125 standard, are high-performance bare conductors specifically designed for primary and secondary overhead power transmission and distribution applications. Utilizing high-strength Aluminum Alloy 6201-T81 wires, these conductors offer a superior balance of mechanical robustness, excellent electrical conductivity, and enhanced resistance to abrasion, making them an ideal and sustainable choice for modern electrical grids.

Key Features

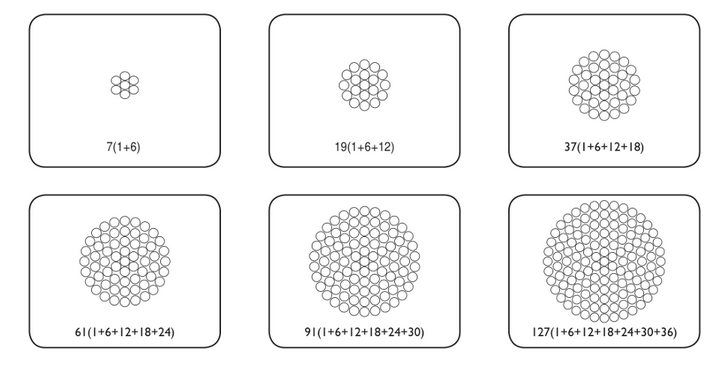

- Shape of Conductor: Stranded circular construction, ensuring optimal flexibility during handling and installation, as well as consistent electrical performance.

- Sectional Area Range: Available in a broad range of sizes from 22 mm² to 1600 mm², accommodating diverse power transmission and distribution requirements.

- Insulation: N/A (Bare Conductor) – designed for overhead applications where ambient air serves as the primary insulation medium.

- Conductor Material: Consists of Aluminum Alloy 6201-T81 wires. This alloy is specifically chosen for its high strength-to-weight ratio, improved sag characteristics, and notably greater resistance to abrasion compared to 1350-H19 grade aluminum conductors. It maintains good electrical conductivity.

- Resistance to Elements: The conductor is inherently resistant to moisture and various weather conditions, contributing to a longer service life and reduced maintenance needs.

- Lightweight and Flexible: These properties make the cable easier to handle, transport, and install, significantly reducing installation effort and costs.

- Recyclability: Given that aluminum is a highly recyclable material, AAAC conductors offer an environmentally friendly option, capable of being repurposed once their operational lifespan is complete.

Application

AAAC conductors conforming to NFC 34 125 are versatile and primarily employed in:

- Primary Overhead Transmission and Distribution Lines: Used as main conductors for high and medium voltage power delivery.

- Secondary Overhead Distribution Networks: Ideal for distributing power to end-users in both urban and rural environments.

- Grounding in Electrical Constructions: Can also be effectively utilized for grounding purposes within various electrical installations.

- Environments Requiring Abrasion Resistance: Their enhanced resistance to abrasion makes them suitable for areas where friction or wear might be a concern.

Standards

Our AAAC - All Aluminum Alloy Conductors are meticulously manufactured and tested to meet or exceed the requirements of the following standards:

- NFC 34 125: This French standard specifically defines the requirements for All Aluminum Alloy Conductors for overhead lines.

- EN 50182: Conductors for overhead lines – Round wire concentric lay stranded conductors, ensuring compliance with broader European specifications.

- Requirements of the National Electrical Code: Designed to align with the safety and installation provisions of relevant National Electrical Codes.

Construction

AAAC conductors are constructed from concentric lay stranded wires of Aluminum Alloy 6201-T81. Similar in appearance to a 1350 grade aluminum conductor, the 6201-T81 alloy provides enhanced mechanical properties, including greater resistance to abrasion. The specific stranding and number of wires are precisely engineered to meet the electrical and mechanical performance criteria stipulated by the NFC 34 125 standard.