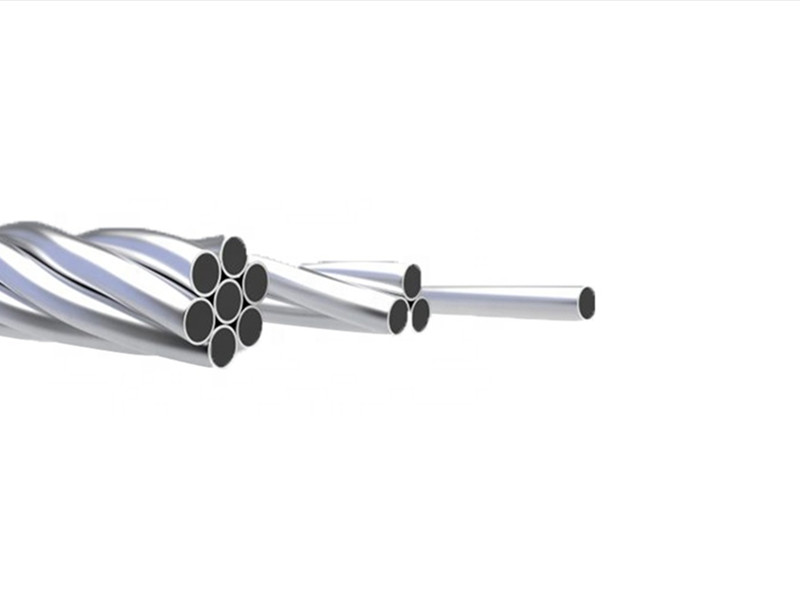

ACS (Aluminum Clad Steel Wire) is a bimetallic conductor consisting of a high-strength steel core evenly coated with a thick layer of pure aluminum. This construction delivers a superior combination of mechanical strength, high conductivity, and excellent corrosion resistance. ACS wire is ideal for applications requiring long spans, exposure to harsh environments, and high durability.

Applications

ACS wire is widely used in various overhead and structural applications, including:

-

Core wire for ACSR/AW (Aluminum Conductor Steel Reinforced / Aluminum Clad)

-

Overhead ground wire (shield wire) and extra high-voltage transmission lines

-

OPGW (Optical Ground Wire) systems

-

Self-damping conductors and other bare overhead conductors

-

Messenger wire, guy wire, and structural support

-

Terminating and splicing components, fencing, and barbed wire in utility infrastructure

-

Ideal for coastal, island, humid, salt fog, or high-pollution areas requiring superior corrosion resistance

Standards

Our ACS wires conform to the following international standards:

-

DIN 48201 – German Standard

-

ASTM B416 – Standard for Aluminum-Clad Steel Wire

-

ASTM B502 – Standard for Concentric-Lay-Stranded ACS Conductors

-

ASTM B415 – Tensile Requirements

-

IEC 61232 – International Electrotechnical Standard

-

AS 1222.2-92 – Australian Standard for Aluminum Clad Wire

Key Features

-

✅ Strong Bonding: The aluminum layer is metallurgically bonded to the steel core, ensuring no flaking or separation during mechanical processing or heat exposure.

-

✅ Corrosion Resistance: Offers 10–20 times greater corrosion resistance than galvanized steel wire, ideal for aggressive environments.

-

✅ High Strength-to-Weight Ratio: Combines the tensile strength of steel with the light weight and conductivity of aluminum.

-

✅ Improved Conductivity: With an aluminum cladding thickness that covers 25% of the cross-sectional area, ACS achieves excellent electrical conductivity.

-

✅ Thermal Stability: Suitable for use in high-temperature operations without performance degradation.

-

✅ Cost-Effective Alternative: Ideal replacement for pure copper wires in many applications, reducing material and installation costs.

Typical Composition

-

Core: High-tensile galvanized steel

-

Outer Layer: Corrosion-resistant aluminum cladding

-

Cladding Thickness: Typically 10%–25% of the overall wire diameter

-

Options: Single-wire or stranded configurations available based on project needs