GSW (Galvanized Steel Wire), meticulously manufactured to conform with the ASTM A475 standard, is a robust and indispensable component in numerous electrical, structural, and telecommunication applications. This specification defines the requirements for zinc-coated steel wire strand, which is engineered to provide an exceptional combination of high tensile strength and superior corrosion resistance due to its protective zinc coating.

CONSTRUCTION

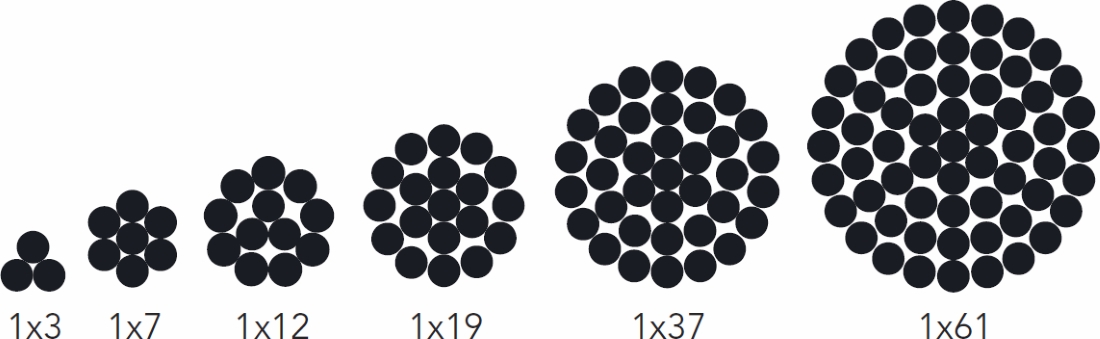

1.The single wires are concentrically stranded and wrapped helically around a central wire.

2.Zinc-coated grade of steel strand wire /guy wire : Class A ,Class B and class C.

Concentrically stranded Galvanized steel wire strand available in class “A”, “B” and “C” galvanizing, “A” being the least heavy and “C” being the most heavy.

GSW-Galvanized Steel Wire Conducutor Construction

Key Aspects and Features of ASTM A475 GSW

Material: The conductor is fundamentally made of high-quality steel, which is then thoroughly coated with a layer of zinc. This zinc coating acts as a sacrificial barrier, providing excellent protection against corrosion in diverse environments.

Standard Compliance: Our GSW adheres strictly to ASTM A475, the definitive standard specification for Zinc-Coated Steel Wire Strand. This standard outlines comprehensive requirements for the zinc coating (thickness, adherence, uniformity) and critical mechanical properties of the wire.

Grades of Zinc Coating: To meet varying environmental demands and service life expectations, GSW is available with different classes of zinc coating:

- Class A: Standard coating thickness.

- Class B: Thicker coating than Class A, offering enhanced corrosion protection.

- Class C: Features the heaviest zinc coating, providing maximum corrosion resistance for the most aggressive environments.

Grades of Strength: GSW is manufactured in various strength grades to suit specific mechanical loading requirements:

- Siemens-Martin

- High-Strength

- Utilities

- Extra-High-Strength These grades ensure the appropriate tensile strength for the intended application.

Construction: GSW can be supplied in two primary constructions:

- Single Wire: For simpler applications where less flexibility is required.

- Multiple Wires Concentrically Stranded: For greater flexibility and higher tensile strength, wires are helically wrapped around a central core wire.

Applications

The unique combination of high strength and excellent corrosion resistance makes ASTM A475 GSW indispensable across a wide range of applications:

- Overhead Ground Wire (Static Wire): Crucially used on overhead power transmission lines to provide a direct path to the ground for lightning strikes, thereby protecting the phase conductors and electrical equipment from damage.

- Guy Wires: Employed to stabilize and support utility poles, communication towers, and other overhead structures, especially in overhead power line infrastructure, by counteracting lateral forces.

- Messenger Cable: Serves as a strong support element for aerial communication cables (e.g., telephone, fiber optic) and other aerial cables, bearing their weight across spans.

- Core of ACSR (Aluminum Conductor Steel Reinforced) Conductors: Provides the essential tensile strength to ACSR conductors, enabling them to span long distances and withstand mechanical stresses while the outer aluminum layers handle electrical conductivity.

- Fencing and General Structural Support: Its strength and corrosion resistance make it suitable for various fencing systems and general outdoor structural support.

Benefits

Choosing GSW conforming to ASTM A475 offers significant advantages for your projects:

- High Tensile Strength: Provides robust mechanical support and resilience, crucial for overhead and tensioned applications.

- Superior Corrosion Resistance: The zinc coating dramatically extends the service life of the wire, reducing maintenance and replacement costs, especially in outdoor and harsh environments.

- Cost-Effectiveness: Offers a favorable balance of performance, durability, and cost, making it an economically viable solution for numerous demanding applications.

- Reliability: Manufactured to stringent ASTM standards, ensuring consistent quality and dependable performance.

For detailed technical specifications, available grades, or to discuss how our ASTM A475 compliant Galvanized Steel Wire can meet your specific project requirements, please contact our sales team.