Concentric Aluminum Cables Application

This specification pertains to PVC insulated single-phase concentric cables featuring circular stranded aluminum conductors, designed for operation up to and including 1000 Volts between phases and 600 Volts to earth.

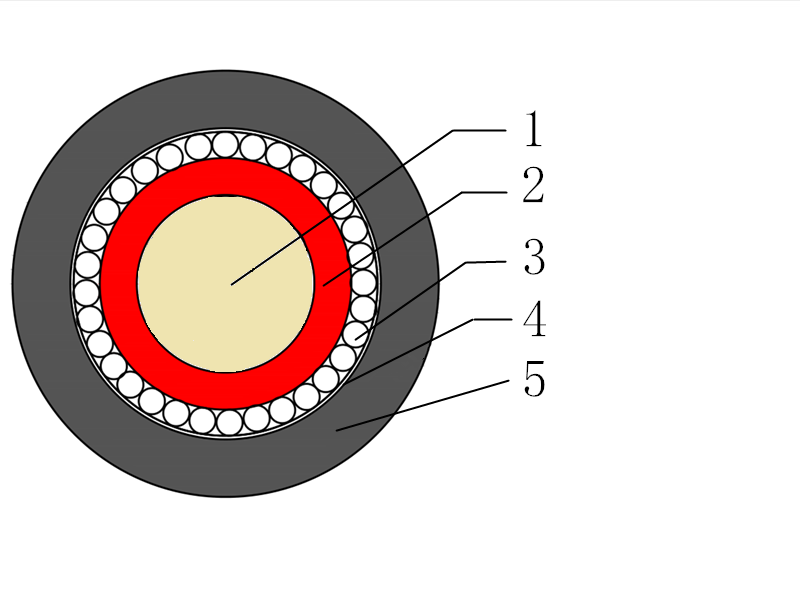

The cable construction includes a central phase conductor, insulated with red PVC, and a concentric layer consisting of bare aluminum wires, which function as a combined neutral-earth conductor, all encased in a black PVC outer sheath.

These concentric cables serve as a crucial electric service entrance from the power distribution network to the meter panel (particularly where preventing 'black' losses or electricity theft is required). They also function as a feeder cable from the meter panel to the main or general distribution panel, in accordance with the National Electrical Code. This type of conductor is suitable for use in both dry and wet locations, can be directly buried, or installed outdoors. Its maximum operating temperature is , and its service voltage across all applications is .

STANDARD

The concentric aluminum cables are designed and manufactured in compliance with:

- IEC 60502-1

- Kenya Standard KS 04-1022

CONSTRUCTION

Aluminum Concentric Cable Construction

Aluminum Concentric Cable Construction

Phase Conductor

The phase conductor shall be circular stranded annealed Aluminum conductors (class 2) as specified in KS 04-1022. The phase conductor shall have a left-hand direction of lay.

Insulation

The insulation of the phase conductor shall be red PVC compound specified in KS 04-1022. It shall be applied by an extrusion process and shall be spark tested in accordance with KS 04-1022.The thickness of insulation, determined in accordance with KS 04-1022, shall be not less than the value given in Table 2 of this specification and the smallest of the measured values shall not fall below the value given in the said table by more than (10% + 0.1mm).

Concentric Layer

The neutral conductor shall be concentric and shall be manufactured from plain annealed aluminum wires in accordance with KS 04-1022. The number of wires and the resistance of the neutral conductor shall comply with Table 2 of this specification.The concentric layer shall be applied with a right hand direction of lay.

Oversheath

The oversheath shall be an extruded layer of black PVC compound as specified in KS 04-1022. The oversheath shall be spark tested in accordance with KS 04-1022.