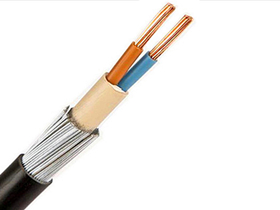

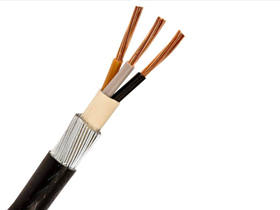

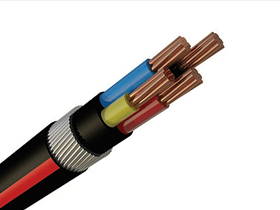

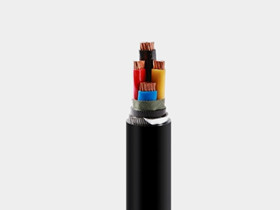

Premium SWA Cables for Industrial, Underground & Outdoor Installations

TOT Wire & Cable is a trusted SWA cable manufacturer and supplier, providing a comprehensive range of Steel Wire Armoured Cables for low and medium voltage power applications. Our SWA power cables are engineered to deliver superior mechanical protection, long-term reliability, and excellent electrical performance in the harshest environments.

Whether you need underground SWA cable for power distribution or heavy-duty industrial wiring, TOT delivers high-quality armoured cables at competitive prices.