PILC cable stands for Paper-Insulated, Lead-Covered cable—a type of high-voltage power cable that was widely used for underground and industrial electrical distribution throughout much of the 20th century.

what is pilc cable

While largely replaced by modern polymer-insulated cables, PILC is still encountered in older installations and some specialized applications. Here's what you need to know.

What Is PILC Cable?

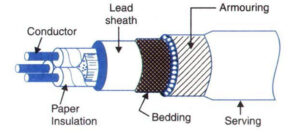

PILC cable is a type of medium-voltage or high-voltage power cable with the following core structure:

✅ Construction:

Conductors: Usually copper or aluminum

Insulation: Layers of oil-impregnated cellulose (paper) insulation

Metallic Sheath: A seamless lead (Pb) or lead-alloy sheath, acting as:

A moisture barrier

A grounding conductor

A shield against electrical interference

Optional Layers:

Armoring (steel tape or wire)

Outer PVC or bituminous jacket

✅ Voltage Range:

Typically used for 2.4 kV to 35 kV applications, though some versions are rated higher.

Where Is PILC Cable Used?

Though outdated for new installations, PILC cables are still in service today, especially in:

🏙️ Urban Underground Power Networks

Utility companies use PILC for buried power distribution

Durable against moisture and mechanical stress

🏭 Industrial Facilities

Steel mills, refineries, or chemical plants with older infrastructure

🌐 Legacy Infrastructure

Installed decades ago, still functioning reliably

Replaced only when maintenance becomes impractical

Advantages of PILC Cables

Despite their age, PILC cables offer some distinct benefits:

| Advantage | Explanation |

|---|---|

| Excellent moisture resistance | Lead sheath is completely watertight |

| High mechanical strength | Withstands compression and soil movement |

| Long service life | Often lasts 40+ years underground |

| Shielding | Built-in electrostatic shielding via lead |

Disadvantages of PILC Cables

Modern polymer-insulated cables (like XLPE) are preferred today due to several downsides of PILC:

Heavy weight: Lead sheath makes the cable bulky and hard to handle

Environmental concerns: Lead is toxic and regulated

Labor-intensive installation and repair

Insulation degradation over time (paper dries or carbonizes)

Difficult to splice without special tools and skills

PILC vs XLPE Cable

| Feature | PILC Cable | XLPE Cable |

|---|---|---|

| Insulation | Oil-impregnated paper | Cross-linked polyethylene (XLPE) |

| Sheath | Lead | Aluminum or polymer jackets |

| Weight | Heavy | Lighter |

| Moisture resistance | Excellent | Good (with outer jacket) |

| Flexibility | Rigid | Flexible |

| Environmental impact | Lead = hazardous | Lead-free |

| Typical use today | Legacy systems | New medium- and high-voltage installations |

Should You Replace PILC Cable?

Utilities often keep PILC cables in place as long as they’re performing well. However, replacement is usually considered when:

Insulation starts to fail

Splices become unreliable

Upgrades or expansion are needed

Regulatory pressure encourages removal of lead-based materials

Conclusion

PILC cable is a legacy power cable type with paper insulation and a protective lead sheath, designed for underground and high-voltage use. While not commonly installed today, it remains an important part of older infrastructure and is valued for its durability and water resistance.

Understanding PILC is essential for anyone working with legacy power grids, urban utilities, or industrial maintenance.

Need Modern Replacements for PILC?

We offer XLPE-insulated medium voltage cables and lead-free armored cables designed to meet today’s standards. Contact us to learn more about compatible alternatives to PILC.