- Home

- Products

Power Cables

- Low Voltage Cables - LV

- ——Low Voltage Non-armored Copper Power Cable

- ——Low Voltage Non-armoured Aluminum Power Cable

- ——Low Voltage Steel Tape Armoured Power Cable

- Medium Voltage Cables - MV

- ——Medium Voltage Armored Power Cable

- ——Medium Voltage Non-armored Power Cable

- High Voltage Cables-HV

- Steel Wire Armored Cable (SWA Cable)

- ——Single Core AWA Armoured Cable

- ——2 Core SWA Armoured Cable

- ——3 Core SWA Armoured Cable

- ——4 Core SWA Armoured Cable

- ——5 Core SWA Armoured Cable

- ——SWA Armoured Cable Specifications

- XLPE Insulated Power Cables

- ——XLPE Insulated Single Core Copper Cable

- ——XLPE Insulated 2 Core Copper Cable

- ——XLPE Insulated 3 Core Copper Cable

- ——XLPE Insulated 4 Core Copper Cable

- ——XLPE Insulated 5 Core Copper Cable

- ——XLPE Insulated 3+1 Core Copper Cable

- ——XLPE Insulated 3+2 Core Copper Cable

- Mineral Insulated Cables

- TPS Cable

Renewable Energy Cables

Control & Signal Cables

- Control Cable

- Instrumentation Cable Supplier & Manufacturer

- High-Performance Coaxial Cable Supplier

- VFD Cable

Installation & Building Wire

- Premium Electrical Wire & Cable Supplier

- MC Cable

- NM-B (Non-Metallic Sheathed) Copper Wire

- UF-B Wire

- MTW Wire

Special Cables

- 4/0 Type W Cable – Heavy Duty Portable Power Solutions

- Trunk Trailer ABS Cable

- SO Cable

- Low Smoke Halogen Free Fire Resistant Cable

- Copper Ground Rods

- Copper Clad Steel Antenna Wire

- Marine Power Cords

- Extra High Voltage (EHV) Submarine Power Cables

- Submersible Pump Wire

- Floating cable

- High Temperature Wire

- EV Automotive High Voltage Silicone Rubber Cable

- Braided Stainless Steel Cable

- LC to LC Fiber Patch Cables

- Your Go-To Flexible Cable Supplier & Manufacturer

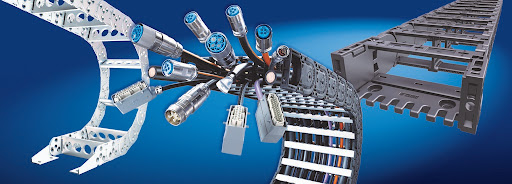

- Drag Chain Cables

- Silicone Rubber Low Temperature Resistant Cable

Overhead & Aerial Cables

- AAC Conductor

- Aerial Bundled Cable (ABC Cable) Supplier & Manufacturer

- ——NFC 33-209 ABC Cable

- ——0.6/1kV Aerial Bundle Cable

- ——Medium Voltage ABC Cable

- ——Tree Wire Spacer Cable

- ——Aluminum URD Cable

- ——Aluminum XHHW SER SEU RHH RHW-2 XLP USE-2

- Aerial Insulation Line (AIL)

- Bare Stranded Conductors Manufacturer & Supplier

- ——ACSR Conductor

- ——AAAC Conductors

- ——ACAR Conductor

- ——Bare Copper Stranded Conductor

- ——CCS Conductor

- ——ACS Condutcor

- ——Guy Wire

- Overhead Service Drop Cable / Overhead Service Wire

- ——Weatherproof Covered Line Wire

- ——Duplex Overhead Service Drop Cable

- ——Triplex Overhead Service Drop Cable

- ——Quadruplex Overhead Service Drop Cable

- Concentric Service Cable – Reliable Power Distribution Solutions

- ——Aluminum Concentric Service Cable

- ——Copper Concentric Service Cable

- ——Concentric Service Cable with Communication Pilot

- Telephone Drop Cable for Reliable Voice & Data Transmission

- ——PVC Parallel Drop Wires

- ——PE Parallel Drop Wires

- About us

- News

- Contact us

News

Stay updated with the newest developments, industry trends, and expert knowledge about various types of wires and cables. Explore our news section for valuable information and insights.

- Home

- News

10 Critical Parameters for Drag Chain Cable Selection

Drag chain cables aren't just flexible cables—they're precision-engineered for millions of flex cycles in one of the harshest cable environments. Get the specifications wrong, and failure is guaranteed. Get them right, and your cables outlast the machine.

Read moreOutdoor Cable Selection: IP Rating, UV Protection, and Temperature Range Explained

Your outdoor cables looked perfect when installed. Six months later, the jacket is cracking, water is getting inside, and you're replacing the entire run. Cost: $8,000 in materials, labor, and downtime. The problem? The cable was rated for outdoor use—but not for YOUR outdoor conditions. UV exposure in Arizona is different from rain in Seattle, which is different from snow in Canada, which is different from coastal salt spray in Florida.

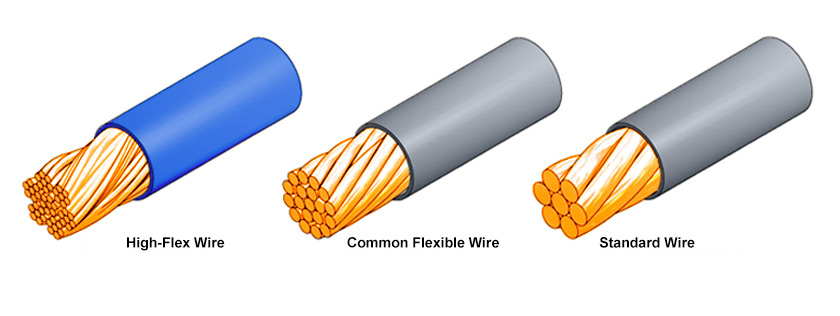

Read moreHigh-Flex Cable vs Standard Cable: When to Upgrade (And When Not To)

High-flex cables aren't always necessary. But when they are, they're irreplaceable. This guide tells you exactly when to upgrade and when to save your money.

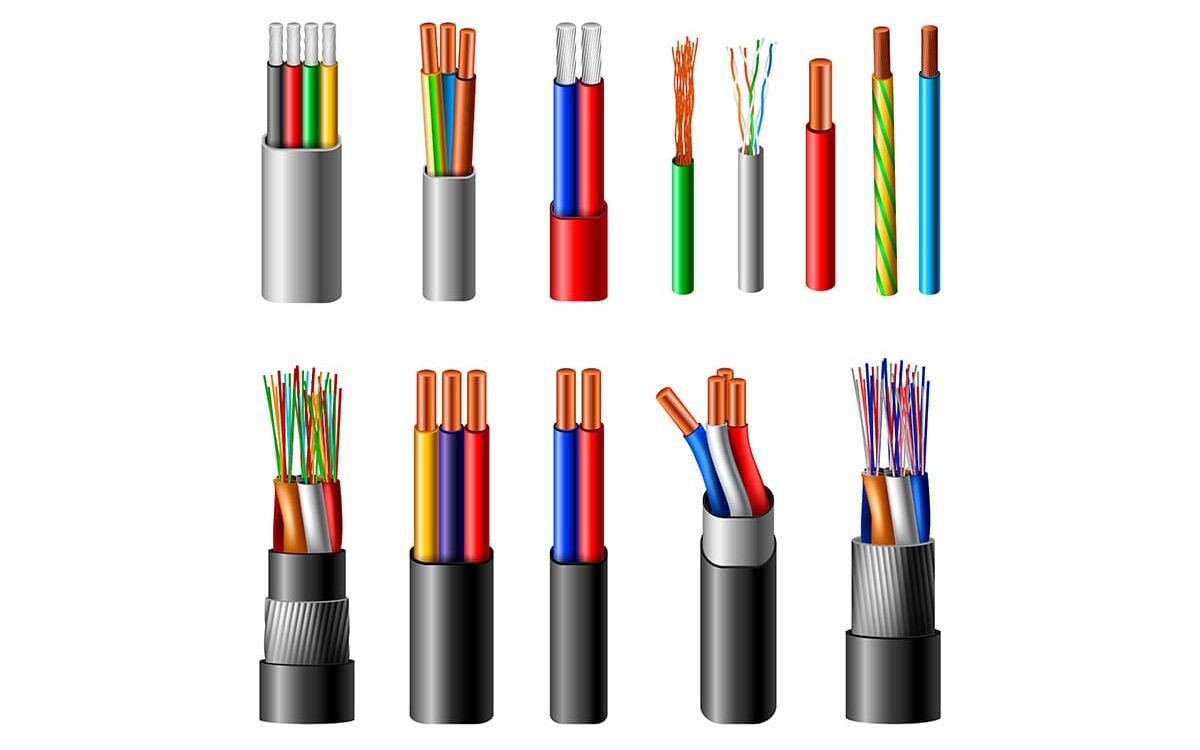

Read moreCable Selection Made Simple: 5 Steps From Requirements to the Right Product

Most people make costly mistakes: buying based on price alone, copying what was used before without understanding why, or choosing cables that fail within months because they don't match the actual operating conditions. This guide gives you a simple 5-step process to confidently select the right cable every time—no electrical engineering degree required.

Read moreIndustrial Automation Cable Selection: The Complete Guide

In industrial automation, cables aren't just wires—they're critical components that determine system reliability, performance, and lifespan. Choose wrong and you'll face constant downtime, mysterious faults, and expensive replacements. Choose right and your system runs flawlessly for decades.

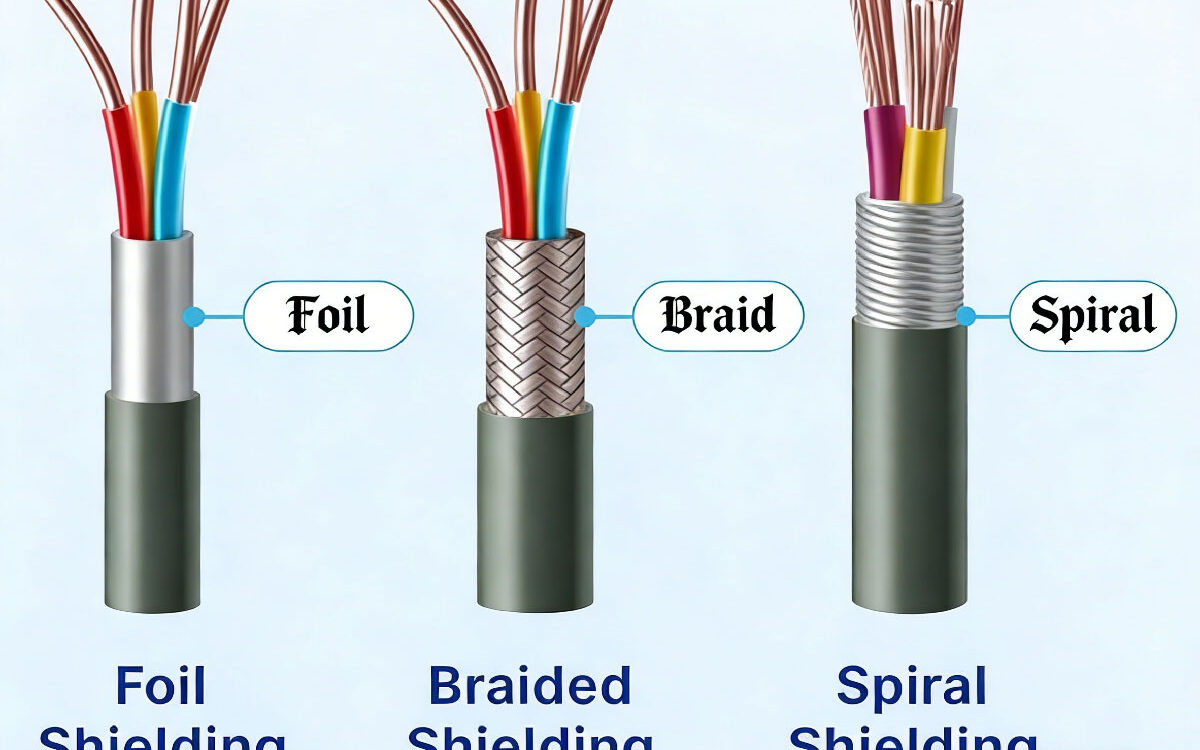

Read moreCable Shielding Explained: Braid vs Foil vs Spiral (Which One Do You Actually Need?)

Cable shielding isn't a one-size-fits-all solution. Braid, foil, and spiral shields each work differently, cost differently, and perform differently. Choose wrong and you'll either waste money on unnecessary protection or leave your signals vulnerable to interference. This guide breaks down the three main shielding types, explains how each works, and tells you exactly when to use each one.

Read moreThe “Nerves” and “Blood Vessels” of Offshore Wind Power: Understanding Optical-Electrical Composite Submarine Cables

Today, most offshore wind farms no longer rely on simple power cables. Instead, they use optical-electrical composite sea cables, which combine high-voltage power transmission and fiber-optic communication into a single integrated system. In many ways, these cables act as both the “blood vessels” and “nervous system” of offshore wind farms—delivering energy while simultaneously transmitting data and monitoring system health.

Read moreCable Ampacity Explained: How to Calculate Current Capacity (And Why It Matters)

Cable ampacity isn't a single number—it's a calculation that depends on how and where you're using the cable. Get it wrong and you risk equipment damage, fire, or code violations. Get it right and your installation is safe, efficient, and code-compliant.

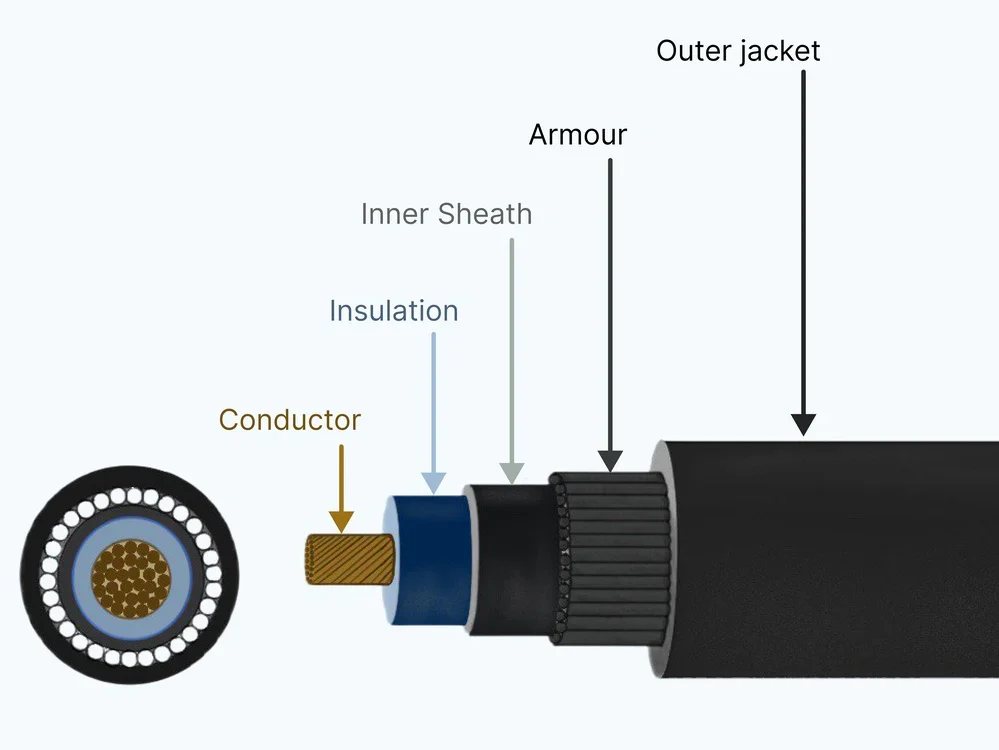

Read moreCable Construction Explained: From Conductor to Jacket (The Practical Guide)

Ever wondered why some cables cost $2 per meter while others cost $20? Or why your "heavy-duty" cable failed after six months while a cheaper one lasted five years? The answer lies in construction—the layers and materials inside the cable.

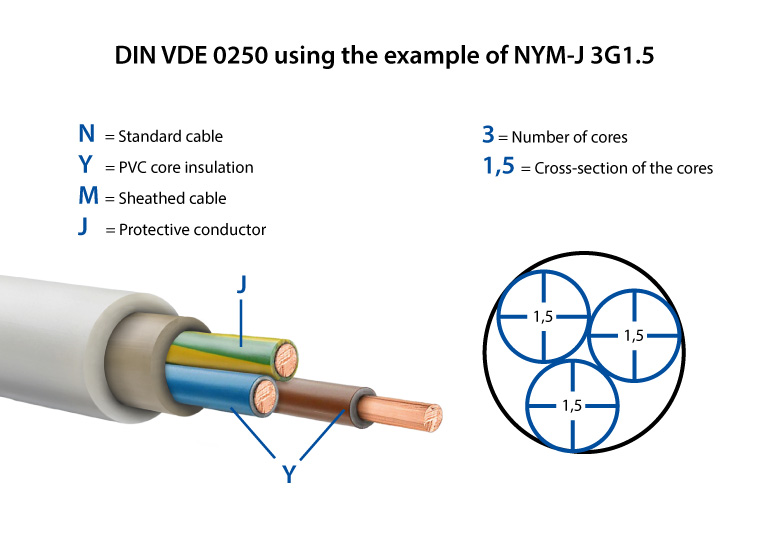

Read moreCable Designation System Decoded: Chinese GB, American NEC, and European IEC Standards Explained

Before we dive into the codes, understand this: cable designation systems exist to compress complex technical specifications into standardized shorthand.

Read more- Low Voltage Cables – LV

- Medium Voltage Cables – MV

- High Voltage Cables-HV

- Steel Wire Armored Cable (SWA Cable)

- XLPE Insulated Power Cables

- Mineral Insulated Cable (MICC/MI Cable)

- TPS Cable

- Control Cable

- Instrumentation Cable

- Coaxial Cable

- VFD Cable

- Computer Cable

- Electrical Wire

- MC Cable

- NM-B (Non-Metallic Sheathed) Copper Wire

- UF-B Underground Feeder Cable

- MTW Wire

- Prefabricated branch cables

- 4/0 Type W Cable

- Trunk Trailer ABS Cable

- SO Cable

- LSZH Cable

- Copper Ground Rods

- Copper Clad Steel Antenna Wire

- High Temperature Wire

- EV Automotive High Voltage Silicone Rubber Cable

- Submersible Pump Wire

- Floating cable

- LC to LC Fiber Patch Cables

- Flexible Cable

- Drag Chain Cables

- Silicone Rubber Low Temperature Resistant Cable

- All-Aluminum Conductors for Overhead Power Lines

- Aerial Bundled Cable (ABC Cable)

- Aerial Insulation Line (AIL)

- Bare Stranded Conductors

- Wind Farm Cables

- Overhead Service Drop Cable

- Concentric Service Cable

- Telephone Drop Cable

- Solar PV Cable

Recent Posts