You open a cable catalog: 3,000 options, wire sizes from 0.5mm² to 500mm², insulation types you've never heard of, prices from $0.50 to $80 per meter. Where do you even start?

Most people make costly mistakes: buying based on price alone, copying what was used before without understanding why, or choosing cables that fail within months because they don't match the actual operating conditions.

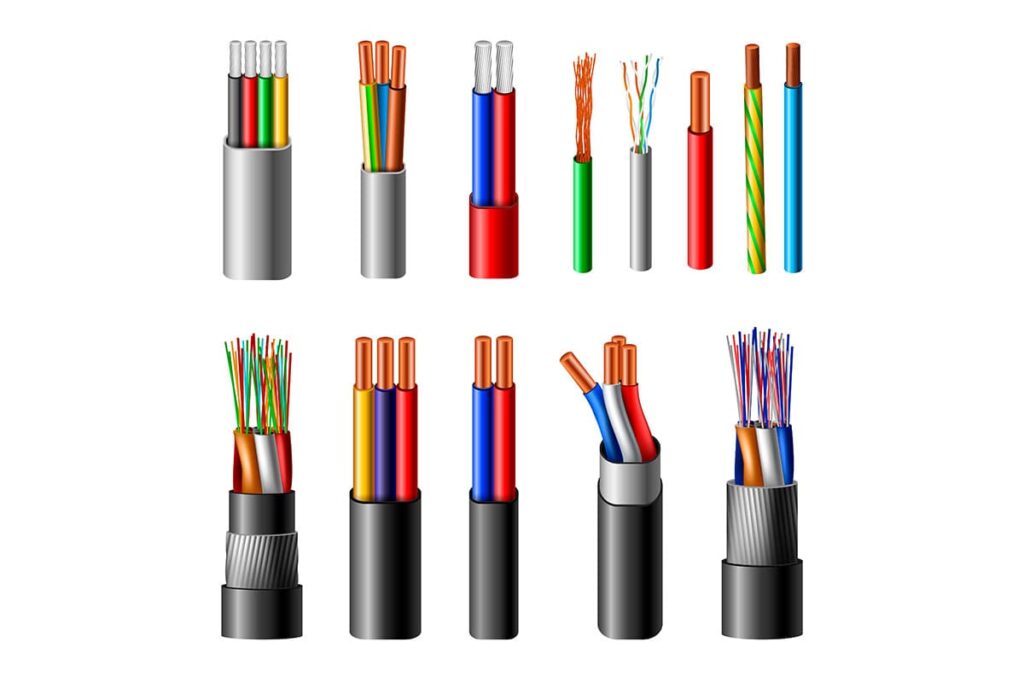

cable selection

This guide gives you a simple 5-step process to confidently select the right cable every time—no electrical engineering degree required.

Why Most Cable Selection Goes Wrong

Common mistakes:

- Starting with wire size instead of requirements

- Choosing based on price alone

- Ignoring environmental conditions

- Using 'equivalent' products that aren't actually equivalent

- Forgetting to check certifications until inspection day

The result: Cables that overheat, fail prematurely, violate code, or cost 3x what you actually needed.

The solution: Follow these 5 steps systematically.

Step 1: Define Your Requirements (Answer These Questions First)

Before looking at any products, understand exactly what you need.

What Are You Connecting?

Be specific:

Power applications:

- '5HP motor to VFD' (not just 'motor cable')

- 'LED lighting, 20 fixtures, 40W each' (not just 'lighting cable')

- 'Welding machine, 240V, 50A' (not just 'power cable')

Signal applications:

- 'Temperature sensor, 4-20mA, 50 meters to PLC' (not just 'sensor cable')

- 'Incremental encoder, 10,000 PPR' (not just 'encoder cable')

- 'PROFIBUS network, 1.5 Mbps' (not just 'data cable')

Why specifics matter: A motor cable and a sensor cable both carry electricity, but their construction is completely different.

What's Your Environment?

Temperature:

- Indoor office (20-30°C) → Standard insulation OK

- Factory floor (35-45°C) → Need temperature derating

- Near ovens (60-80°C) → Need high-temp rated

- Outdoor winter (-20°C) → Need cold-flexible materials

Exposure:

- Dry indoor → PVC jacket fine

- Occasional moisture → Water-resistant needed

- Constant oil exposure → PUR/neoprene required

- Outdoor sun → UV-resistant mandatory

- Chemicals → Check compatibility charts

Mechanical:

- Protected (in conduit) → Standard construction

- Light contact → Robust jacket

- Heavy abuse → Armored cable

- Burial → Armored, moisture-proof

Electrical noise:

- Clean office → No shielding needed

- Near motors/VFDs → Shielding required

- Heavy industrial → Premium shielding needed

How Will It Move?

This dramatically affects cost:

Fixed installation (never moves):

- Solid or basic stranded conductors

- Standard construction

- Cost: $

Occasional flexing (moved sometimes):

- Flexible stranded conductors

- Robust construction

- Cost: $$

Frequent flexing (daily movement):

- High-flex rated conductors

- Special construction

- Cost: $$$

Continuous motion (drag chains, robots):

- Ultra-flexible, millions of cycles

- Premium construction

- Cost: $$$$

What Certifications Do You Need?

Geographic:

- North America → UL/CSA required

- Europe → CE marking required

- China → CCC required

Installation location:

- Standard indoor → Basic flame rating

- Vertical shafts → Riser rated (CMR)

- Air handling → Plenum rated (CMP)

- Hazardous areas → Special ratings

Industry-specific:

- Industrial networks → Protocol certifications (PROFIBUS, EtherCAT)

- Marine → Marine approvals

- Medical → Medical certifications

Budget and Timeline

Be realistic:

- What can you actually spend per meter?

- Is this temporary (1-2 years) or permanent (20+ years)?

- What's the cost of failure? ($1,000/hour downtime vs $100 repair)

- When do you need it? (Stock vs 4-week lead time)

Step 2: Calculate Technical Specifications

Now translate your requirements into specific numbers.

Electrical Requirements

For power cables:

Calculate current (simple method):

- Find your load current:

- Motor: Check nameplate FLA (Full Load Amps)

- Resistive: Watts ÷ Volts = Amps

- Multiple loads: Add them up

- Apply safety factor:

- Continuous loads (>3 hours): Current × 1.25

- Intermittent: Current × 1.0

- Account for conditions:

- Hot environment (40-50°C): Divide by 0.8

- Bundled cables: Divide by 0.8

- Both: Divide by 0.65

Example:

10HP motor, 460V, nameplate 14A

Safety factor: 14A × 1.25 = 17.5A

Hot factory (45°C): 17.5A ÷ 0.8 = 21.9A

Bundled with other cables: 21.9A ÷ 0.8 = 27.4A

Minimum cable capacity needed: 28A

Select voltage rating:

- 120V system → 300V cable minimum

- 240V system → 600V cable

- 480V system → 600V cable

-

1000V → Consult engineer

For signal/data cables:

Key specifications:

- Analog (4-20mA, 0-10V) → Need shielding

- High-speed digital → Specific impedance (100Ω, 120Ω, 150Ω)

- Pulse signals (encoders) → Low capacitance

- Networks → Protocol-specific specs

Material Selection

Conductor material:

- Copper → Use for 95% of applications (best choice)

- Tinned copper → Marine, high-temp, outdoor (+15% cost)

- Aluminum → Only for very large power cables (special connectors needed)

- Never CCA (copper-clad aluminum) → Not code-compliant, causes failures

Conductor stranding (match to movement):

| Movement | Stranding | Flex Life | Cost |

|---|---|---|---|

| Fixed | Solid or 7-strand | <100 cycles | $ |

| Occasional | 19-40 strands | 1K-10K cycles | $$ |

| Frequent | 50-100 strands | 10K-100K cycles | $$$ |

| Continuous | 1000+ strands | 1M-5M cycles | $$$$ |

Insulation material (match to environment):

| Material | Temp Range | Best For | Cost |

|---|---|---|---|

| PVC | -10 to +70°C | Indoor, protected | $ |

| XLPE | -40 to +90°C | Power, industrial | $$ |

| TPE | -40 to +90°C | Flexible, modern | $$-$$$ |

| PUR | -40 to +80°C | High-flex, oil | $$$ |

| Silicone | -60 to +180°C | Extreme temp | $$$$ |

Shielding (do you need it?):

NO shielding:

- Simple power (lights, heaters)

- Low-speed signals in clean areas

- Save 20-40% on cost

YES shielding:

- Near motors or VFDs

- Instrumentation and sensors

- Data/network cables

- High-speed signals

Shielding types:

- Foil → Fixed installation, high-frequency noise, cheapest

- Braid → Flexing applications, low-frequency noise, stronger

- Foil + Braid → Best performance, high-EMI areas, most expensive

Jacket material (outer protection):

| Jacket | Environment | Cost |

|---|---|---|

| PVC | Indoor only | $ |

| PE | Outdoor, UV | $$ |

| PUR | Flex, oil, industrial | $$$ |

| Neoprene | Heavy-duty portable | $$$ |

Special Features

Armor (when needed):

- Direct burial → Steel wire armor

- Heavy equipment areas → Steel tape armor

- Rodent risk → Armored cable

- Protected conduit → No armor needed

Flame ratings:

- Standard indoor → CM rating

- Between floors → Riser (CMR)

- Air ducts → Plenum (CMP)

- Public spaces → LSZH (Low Smoke Zero Halogen)

Step 3: Find Matching Products

Translate to Cable Designations

North America:

- Building wire: THHN, THWN, XHHW

- Portable: SOOW, SJOOW

- Industrial: VFD cable, servo cable

- Tray: TC-ER, Type MC

Europe:

- Building: H07V-U (solid), H07V-K (stranded)

- Flexible: H07RN-F

- Power: NYY, NYM

- Control: LIYCY, ÖLFLEX

China:

- Building: BV, BVR

- Power: YJV, YJV22 (armored)

- Control: KVVP, RVV

Compare Multiple Suppliers

Get quotes from 3+ sources:

Compare these factors:

| Factor | What to Check |

|---|---|

| Specifications | Meets ALL your requirements? |

| Ampacity | Rated for your calculated current? |

| Certifications | Has required UL/CE/CSA? |

| Price | Per meter + shipping + taxes |

| Lead time | Stock or special order? |

| Support | Technical help available? |

Create comparison table:

| Supplier | Product | Specs Match? | Price/m | Lead Time | Total Cost |

|---|---|---|---|---|---|

| A | Brand X | Yes | $4.50 | Stock | $450 (100m) |

| B | Generic | Partial | $2.80 | 2 weeks | $280 |

| C | Premium | Exceeds | $6.20 | 1 week | $620 |

Request Documentation

Before buying, get:

- Full specification sheet

- Certification documents (UL, CE, etc.)

- Test reports (if available)

- Installation instructions

For large orders:

- Request physical samples

- Test flexibility and handling

- Verify markings are correct

- Check termination ease

Step 4: Verify Compatibility

Before final purchase, confirm everything works together.

Physical Fit

Conduit fill check:

Quick calculation:

Conduit area × 40% = Max cable area

Example: 1' conduit = 544mm² × 0.40 = 218mm² max

Cable 8mm diameter = π × 4² = 50mm²

Max cables: 218 ÷ 50 = 4 cables

Bend radius check:

- Minimum bend radius: 8-10× cable diameter

- Can you achieve this in actual installation?

- Consider multiple bends (cumulative stress)

Connector compatibility:

- Cable fits in connector?

- Conductor size matches terminal?

- Shielded cable needs shielded connector?

Electrical Verification

Voltage drop calculation:

Simple formula:

Voltage Drop % = (Cable Resistance × Current × Length × 2) ÷ (Voltage × 1000)

Example:

50m run, 10 AWG, 20A, 120V

Resistance = 3.3 Ω per 1000m

VD% = (3.3 × 20 × 50 × 2) ÷ (120 × 1000) = 5.5%

Acceptable limits:

- Lighting/general: <5%

- Motors: <3%

- Sensitive equipment: <2%

- If too high: Increase wire size

Impedance matching (data cables):

- Ethernet: 100 ± 15Ω

- PROFIBUS: 150 ± 15Ω

- RS-485: 120Ω

- Use specified cables, don't substitute

Final Checks

Environment:

- Temperature rating exceeds ambient?

- Jacket resists actual chemicals?

- UV rating if outdoor exposure?

Code compliance:

- Cable type approved for installation method?

- Certifications valid for your location?

- Local inspector will accept?

Installation feasibility:

- Team can install this type?

- Standard tools adequate?

- Weight manageable?

Step 5: Order and Document

Calculate Quantity

Don't order exact measured length!

Add contingencies:

- Terminations: +5%

- Routing inefficiency: +8%

- Installation errors: +5%

- Future repairs: +10%

- Total: +25-30% minimum

Example:

Measured need: 80m

Contingency: 80m × 1.25 = 100m

Round up to standard: Order 105m

Create Documentation

Record for future reference:

Order details:

- Supplier and order date

- Product: manufacturer, model, specs

- Quantity and price

- Delivery date

Technical specs:

- Conductor: size, material, stranding

- Insulation: type, temperature

- Jacket: material, color

- Shielding: type, coverage

- Certifications: UL, CE, etc.

Installation info:

- Circuit identifier

- Routing/location

- Installation date

- Installer name

- Test results

Post-Installation Verification

After installation:

Visual inspection:

- Proper routing and support

- Bend radius not violated

- Protection adequate

- Labels in place

Electrical tests:

- Continuity on all conductors

- Insulation resistance (megohm test)

- Ground continuity

- Voltage drop under load

Performance check:

- Equipment operates correctly

- No interference/noise

- Temperature normal

- Movement smooth (if applicable)

Document:

- Update as-built drawings

- Record test results

- Note any issues

- File for maintenance

Real-World Examples

Example 1: Office Lighting (Simple)

Step 1 - Requirements:

- 20 LED fixtures, 40W each = 800W

- Indoor office, 20-25°C, clean

- Fixed installation in ceiling

- Need UL listing

Step 2 - Specs:

- Current: 800W ÷ 120V = 6.7A × 1.25 = 8.4A

- Voltage: 600V rating

- Material: Copper solid, PVC insulation

- No shielding needed

Step 3 - Product:

- 14 AWG THHN building wire

- UL listed, 20A rating

- Stock available

Step 4 - Verify:

- Voltage drop <2%: ✓

- Conduit fill OK: ✓

- Code compliant: ✓

Step 5 - Order:

- 100m each (black/white/green)

- Cost: $0.45/m = $135 total

- Result: Simple, economical, correct

Example 2: Industrial Motor (Complex)

Step 1 - Requirements:

- 5HP motor with VFD

- Factory, 40°C, oil mist, high EMI

- Fixed conduit, 35m run

- UL/CSA required

Step 2 - Specs:

- Current: 7.6A × 1.25 × 1.2 (VFD) = 11.4A

- Hot environment: 11.4A ÷ 0.82 = 13.9A

- Shielded cable required (VFD EMI)

- PUR jacket (oil exposure)

Step 3 - Product:

- VFD-rated cable, 12 AWG, 4-conductor

- 85% copper braid shield

- 25A rating (after corrections = 20.5A) ✓

Step 4 - Verify:

- Shield termination: 360° planned

- Bend radius: Achievable

- Certs: UL/CSA confirmed

Step 5 - Order:

- 50m (35m + 15m contingency)

- Cost: $6.50/m = $325

- Result: Reliable, worth premium

Example 3: Robot Cable (Premium)

Step 1 - Requirements:

- 4-axis robot, power + signals

- Warehouse, -5 to +35°C, UV

- 2 million flex cycles needed

- Downtime = $5K/hour

Step 2 - Specs:

- Ultra-flexible (Class 6)

- Spiral shield for flex

- PUR jacket for UV/abrasion

- Min 2M cycle rating

Step 3 - Product:

- Lapp ÖLFLEX ROBOT F1

- 5M cycle rating

- Torsion rated

Step 4 - Verify:

- Bend radius: 270mm, robot allows 300mm ✓

- Weight: Within payload ✓

- Special connectors: Ordered ✓

Step 5 - Order:

- 15m (12m + 3m spare)

- Cost: $45/m = $675

- Result: Premium justified by criticality

Common Mistakes to Avoid

❌ Mistake 1: Skipping Step 1

Problem: 'I just need 10 AWG wire' Result: Wrong type for application Fix: Always define requirements first

❌ Mistake 2: Price Shopping Only

Problem: 'This $2 cable looks like that $8 cable' Result: Inadequate construction, early failure Fix: Compare total cost of ownership

❌ Mistake 3: Ignoring Environment

Problem: 'It's only sometimes oily' Result: Jacket fails in 6-12 months Fix: Assess worst-case conditions

❌ Mistake 4: Wrong Flex Rating

Problem: Standard cable in drag chain Result: Fails in weeks Fix: Calculate actual flex cycles needed

❌ Mistake 5: Forgetting Certifications

Problem: 'Install now, worry later' Result: Failed inspection, rework Fix: Verify certs before ordering

❌ Mistake 6: Exact Length Order

Problem: Ordering measured length only Result: Not enough for terminations Fix: Add 25-30% contingency

Quick Decision Flowchart

START: What are you connecting?

Power (motors, lighting)

- Fixed → Building wire (THHN)

- Portable → Flexible cord (SOOW)

- Continuous flex → High-flex cable

- With VFD → Add shielding

Signals (sensors, encoders)

- Simple digital → Control cable

- Analog → Shielded twisted pair

- High-speed → Low-capacitance shielded

Data (networks)

- Office → Cat5e/6

- Industrial → Shielded Ethernet

- Fieldbus → Protocol-specific

Check environment:

- Outdoor → UV jacket

- Chemicals → PUR/neoprene

- High temp → Silicone/XLPE

- Cold → Cold-rated

Check movement:

- None → Standard

- Some → Stranded

- Continuous → High-flex

Check certifications:

- USA → UL/CSA

- Europe → CE

- Special → Per requirement

Your Action Checklist

☐ Step 1: Requirements (20 min)

- [ ] Define specific application

- [ ] Assess environment honestly

- [ ] Determine movement needs

- [ ] List required certifications

☐ Step 2: Specifications (30 min)

- [ ] Calculate current requirements

- [ ] Select appropriate materials

- [ ] Determine if shielding needed

- [ ] Choose ratings

☐ Step 3: Product Search (1 hour)

- [ ] Find 3+ matching products

- [ ] Compare specs and pricing

- [ ] Request documentation

- [ ] Get samples if needed

☐ Step 4: Verification (30 min)

- [ ] Check physical compatibility

- [ ] Verify electrical performance

- [ ] Confirm code compliance

- [ ] Assess installation feasibility

☐ Step 5: Order (20 min)

- [ ] Calculate quantity with contingency

- [ ] Create specification document

- [ ] Place order

- [ ] Plan installation verification

Total time: 3-4 hours Value: Cable that lasts its designed lifetime

The Bottom Line

These 5 steps ensure you:

- Understand needs before shopping

- Match specs to actual conditions

- Compare products objectively

- Catch errors before purchase

- Document for future reference

Time invested: 3-4 hours for typical project Time saved: Days to weeks avoiding wrong products Money saved: 10x cable cost by preventing failures

The next time you need cable, don't start with a catalog. Start with Step 1.

Now you have a proven process. No more guessing, no more costly mistakes—just systematic selection based on your actual requirements.