You're about to buy cables for a new machine. The salesperson pushes 'high-flex' cables at 5x the price of standard cables. Are they worth it, or just an upsell?

Or worse: You installed standard cables to save money. Three months later, they've failed, and your production line is down. The replacement cost—including downtime, labor, and rush shipping—is now 10x what you 'saved.'

High-flex cables aren't always necessary. But when they are, they're irreplaceable. This guide tells you exactly when to upgrade and when to save your money.

High-Flex Cable vs Standard Cable

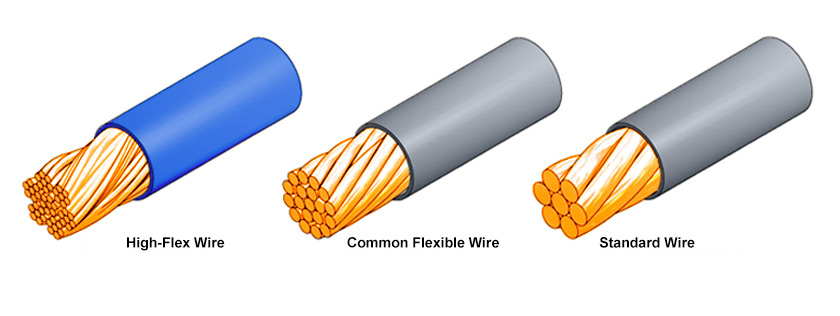

What Makes High-Flex Cables Different

Before deciding if you need high-flex, understand what you're actually paying for.

Standard Cable Construction

Typical features:

- Conductor: 7-19 strands (Class B stranding)

- Insulation: Standard PVC or rubber

- Jacket: Regular PVC or basic rubber

- Design: Cost-optimized for fixed installations

- Flex life: 100-1,000 bend cycles

- Cost: $ (baseline)

Good for:

- Fixed installations

- Permanent wiring

- Occasional movement (moving equipment once in a while)

Fails when:

- Bent repeatedly in same location

- Used in continuous motion applications

- Subjected to vibration or flexing

High-Flex Cable Construction

Specialized features:

- Conductor: 100-1,000+ ultra-fine strands (Class 5/6)

- Special lay: Conductors arranged in precise patterns

- Insulation: Flexible compounds (TPE, special PVC)

- Fillers: Talc or special materials reduce friction

- Jacket: High-performance PUR, TPE, or neoprene

- Design: Engineered for millions of flex cycles

- Flex life: 100,000 to 5+ million cycles

- Cost: $$$-$$$$$ (3-10x standard)

Good for:

- Drag chains and cable carriers

- Robotic applications

- Continuous motion machinery

- High-cycle flexing

Worth it when:

- Downtime cost exceeds cable cost

- Replacement is difficult or expensive

- Application genuinely requires flex cycles

The Flex Life Reality: Numbers That Matter

Understanding flex cycles is key to making the right decision.

What Is a Flex Cycle?

One flex cycle = one complete bend and return to straight

Example: Drag chain moving back and forth

- Start position → Extended → Return to start = 1 cycle

Typical Flex Life by Cable Type

| Cable Type | Flex Cycles | Example Cost/m | Cost per Million Cycles |

|---|---|---|---|

| Standard building wire | 100-500 | $0.50 | $1,000-5,000 |

| Flexible cord (Class C) | 1K-5K | $1.50 | $300-1,500 |

| High-flex rated | 100K-500K | $8 | $16-80 |

| Ultra high-flex | 1M-5M | $25 | $5-25 |

| Premium robot cable | 5M-10M | $50 | $5-10 |

The surprising truth: Premium cables are cheaper per flex cycle than standard cables.

Calculate Your Actual Flex Cycles

Formula:

Total Cycles = Cycles per minute × Minutes per hour × Hours per day × Days per year × Years

Example - CNC machine drag chain:

- 30 cycles/min (machine movement)

- 60 min/hour × 16 hours/day (2 shifts)

- 250 days/year

- 5 year lifespan target

Total = 30 × 60 × 16 × 250 × 5 = 36,000,000 cycles

This application needs ultra high-flex cable (5M+ rating)

Standard cable would fail in:

500 cycles ÷ 30 cycles/min = 16 minutes

When Standard Cable Is Perfectly Fine

Don't waste money on high-flex when standard works.

Fixed Installations

Characteristics:

- Cable installed once, never moves

- Run in conduit, cable tray, or on walls

- No vibration or movement expected

- Easy access for future replacement

Examples:

- Building power distribution

- Lighting circuits

- Fixed equipment connections

- Control panel wiring

Use standard cable:

- Building wire (THHN, H07V-U)

- Standard control cable

- Basic instrumentation cable

Cost savings: 80-95%

Real example:

- Machine control panel to fixed sensor, 20 meters

- Standard cable: $1.50/m × 20m = $30

- High-flex cable: $12/m × 20m = $240

- Savings: $210 (money wasted on unnecessary feature)

Occasional Movement

Characteristics:

- Equipment moved for maintenance (monthly or less)

- Portable tools used occasionally

- Cable flexing happens but infrequently

- Lifetime flex cycles: <10,000

Examples:

- Portable power tools used occasionally

- Equipment serviced monthly

- Test equipment moved between stations

- Movable machinery (adjusted then fixed)

Use flexible cable (not high-flex):

- SOOW portable cord

- H07RN-F flexible cable

- Standard flexible control cable

Cost savings: 60-80%

Real example:

- Portable grinder, 10 meter cord, used 2 hours/week

- Flexible cord: $3/m × 10m = $30

- High-flex cable: $15/m × 10m = $150

- Expected cycles over 5 years: ~5,000

- Flexible cord adequate, saves $120

Low-Cycle Flex Applications

Characteristics:

- Regular flexing but low frequency

- Lifetime cycles: 10,000-50,000

- Not continuous motion

- 1-2 year replacement acceptable

Examples:

- Door/gate connections (opens/closes daily)

- Equipment dress cables (flexes when machine operates)

- Occasional automated movement

Use enhanced flexible cable:

- Premium flexible cord

- Flex-rated control cable (not ultra-flex)

Cost savings: 40-60%

When You MUST Upgrade to High-Flex

These applications destroy standard cables in days or weeks.

Drag Chains and Cable Carriers

Why high-flex is mandatory:

- Continuous back-and-forth motion

- Thousands of cycles per day

- Constrained bend radius

- Multiple cables rubbing together

Typical cycle counts:

- CNC machine: 5,000-15,000 cycles/day

- Pick-and-place: 20,000-50,000 cycles/day

- Gantry system: 10,000-30,000 cycles/day

Over 5 years: 9-45 million cycles

Required cable specs:

- Class 5 or 6 stranding (fine conductors)

- Flex-rated insulation (TPE or PUR)

- Talc or special filler (reduces friction)

- PUR jacket (abrasion resistant)

- Rated for 1M+ cycles minimum

Cost comparison:

Standard cable: $2/m, fails in 1 month

→ 60 replacements over 5 years

→ Cost: 60 × ($2 + $50 labor + $500 downtime) = $33,120

High-flex cable: $15/m, lasts 5 years

→ 1 installation

→ Cost: $15 + $50 labor = $65

Savings: $33,055 (509x return on investment)

Don't even consider standard cable for this application.

Industrial Robots

Why high-flex is mandatory:

- Multi-axis movement (complex motion)

- Torsion at joints (twisting stress)

- Millions of cycles over robot lifetime

- Replacement extremely costly

Typical requirements:

- 6-axis robot: 2-5 million cycles

- SCARA robot: 3-8 million cycles

- Delta robot: 5-10 million cycles

Required cable specs:

- Ultra-fine stranding (rope-lay construction)

- Torsion-resistant design

- Served shield (spiral, not braid)

- Premium PUR jacket

- Rated for 5M+ cycles

- Often 10-20x cost of standard

Real example:

- Automotive welding robot, 4m cable

- Standard cable: Fails in 2 weeks, $200 replacement + $5,000 downtime per failure

- Robot cable: $80/m × 4m = $320, lasts robot lifetime (5+ years)

- Standard cable over 5 years: ~130 failures × $5,200 = $676,000

- High-flex saves: $675,680

For robots: Always use manufacturer-specified or premium robot cable.

Continuous Flexing Applications

Characteristics:

- Non-stop movement during operation

- High frequency (>100 cycles/hour)

- Expected lifetime: 500,000+ cycles

Examples:

- Automated packaging lines

- Conveyor systems with moving components

- Textile machinery

- Printing equipment

- Automated warehouse systems

Required cable:

- Minimum 500K cycle rating

- Proper bend radius maintained

- Installation follows manufacturer guidelines

Rule of thumb:

If cycles/day × days/year × years > 100,000

→ High-flex cable required

High-Vibration Environments

Why high-flex helps:

- Vibration = repeated micro-flexing

- Standard cable conductors fatigue and break

- Failures often intermittent (hard to diagnose)

Examples:

- Cables on vibrating machinery

- Connections to motors or compressors

- Marine applications (engine room)

- Heavy equipment

Solution:

- High-flex cable or vibration-rated cable

- Proper strain relief critical

- Allow slack for vibration absorption

The Gray Area: When It's Not Obvious

Some applications fall between 'definitely standard' and 'must be high-flex.'

Cable Dress to Moving Equipment

Scenario: Cable from fixed point to machine that moves occasionally

Factors to consider:

Use standard if:

- Machine moves <10 times per day

- Movement is slow and gentle

- Cable has generous slack (loose loop)

- Replacement is easy and cheap

Upgrade to high-flex if:

- Machine moves 50+ times per day

- Movement is rapid or jerky

- Limited space (tight bending)

- Replacement requires production shutdown

Real example - Injection molding machine:

- Mold opens/closes: 200 cycles/day

- 250 days/year = 50,000 cycles/year

- 5 years = 250,000 total cycles

- Standard cable: Fails after ~1,000 cycles (5 days)

- Verdict: High-flex required

Robotic Arms with Low Duty Cycle

Scenario: Robot operates intermittently, not continuously

Factors:

Standard flex-rated may work if:

- Robot runs <4 hours/day

- Slow movements, gentle on cables

- Not welding/high-EMI environment

- Budget very constrained

Upgrade to robot-rated if:

- Any welding application (spatter damage)

- High speeds or accelerations

- Expected lifespan >3 years

- Downtime cost >$1,000/hour

Conservative approach: Use robot cable anyway. The cost difference ($500-1,000) is insignificant compared to one failure.

Festoon Systems

Scenario: Cables hang in loops, travel horizontally

Characteristics:

- Less severe than drag chains (no constrained bending)

- But still continuous motion

- Weight and sag create stress

Cable selection:

- Short spans (<5m): High-flex rated adequate

- Long spans (>5m): Premium high-flex or festoon-specific

- Heavy cables: Reinforced or with messenger wire

Typical lifespan targets:

- 500K-2M cycles depending on speed and weight

Cost-Benefit Analysis Framework

Use this decision matrix:

Step 1: Calculate Replacement Cost

Total replacement cost includes:

- New cable cost

- Labor to remove and install

- Downtime cost (production loss)

- Emergency service premium (if unplanned)

Example:

Cable: $100

Labor: $200 (4 hours @ $50/hr)

Downtime: $5,000 (5 hours @ $1,000/hr)

Emergency: $500 (rush shipping)

Total replacement cost: $5,800

Step 2: Estimate Lifetime Cycles

Use the formula from earlier:

Cycles per min × 60 × hours per day × days per year × years

Step 3: Calculate Expected Failures

Standard cable:

Total lifetime cycles ÷ Cable flex rating = Number of failures

Example: 1,000,000 cycles ÷ 500 cycle rating = 2,000 failures

High-flex cable:

1,000,000 cycles ÷ 2,000,000 cycle rating = 0.5 failures (probably 1)

Step 4: Compare Total Cost

Standard cable total cost:

(Initial cost + installation) + (Failures × Replacement cost)

Example:

($50 + $50) + (2,000 × $5,800) = $11,600,100

High-flex cable total cost:

(Initial cost + installation) + (Failures × Replacement cost)

Example:

($400 + $50) + (1 × $5,800) = $6,250

Savings: $11,593,850

(Extreme example to illustrate the point—adjust for your actual numbers)

Decision Rule

Use high-flex if:

(High-flex cost) < (Standard cost + (Expected failures × Replacement cost))

Usually, if you expect more than 1-2 failures over the equipment lifetime, high-flex pays for itself.

Installation Matters: Make Your Cable Last

Even the best high-flex cable fails if installed wrong.

Critical Installation Factors

Bend Radius:

- Manufacturer specifies minimum (typically 10x diameter)

- Never exceed this in actual installation

- Measure actual radius, don't guess

- Multiple bends are cumulative (stress adds up)

Cable Carrier Sizing:

- Fill ratio: 50-70% maximum (cables need room to move)

- Inner radius matches cable minimum bend radius

- Width prevents cable stacking/piling

- Dividers separate power and signal cables

Support and Strain Relief:

- Both ends must be properly secured

- No tension on cable during motion

- Allow slight slack (not too tight)

- Use proper cable glands

Speed and Acceleration:

- High-flex cables have speed ratings

- Rapid acceleration worse than high steady speed

- Exceed ratings = shortened life

Environment:

- Keep cables clean (chips, coolant, etc. cause wear)

- Verify temperature within rating

- Check for chemical exposure

- Protect from UV if applicable

Common Installation Mistakes

Mistake 1: Too tight bend radius

- Cable looks fine but fails quickly

- Conductors break at bend point

- Solution: Use larger radius carrier or fewer cables

Mistake 2: Overfilled carrier

- Cables can't move freely

- Increased friction and wear

- Solution: Larger carrier or multiple carriers

Mistake 3: Mixed cable types

- Standard and high-flex together in carrier

- Standard cables fail and damage others

- Solution: All cables in carrier should be same flex rating

Mistake 4: No strain relief

- Cable pulls at connectors

- Premature connector failure

- Solution: Proper cable glands and securing

Quick Decision Guide

Fixed Installation

- Never moves → Standard building wire

- Moved for maintenance (monthly) → Standard cable

- Cost factor: 1x

Occasional Flex

- Portable tools (used occasionally) → Flexible cord

- Equipment adjustment (weekly) → Flexible cable

- Lifetime cycles: <10,000

- Cost factor: 2-3x

Frequent Flex

- Daily movement → Enhanced flexible cable

- Equipment dress (50-200 cycles/day) → Flex-rated cable

- Lifetime cycles: 10,000-100,000

- Cost factor: 3-5x

Continuous Motion

- Drag chains → High-flex rated cable

- Cable carriers → High-flex rated (1M+ cycles)

- Lifetime cycles: 100,000-2M

- Cost factor: 5-8x

Extreme Flex

- Industrial robots → Ultra high-flex or robot cable

- High-speed automation → Premium high-flex

- Lifetime cycles: 2M-10M

- Cost factor: 10-20x

The Bottom Line

High-flex cables are not always worth it—but when they are, they're irreplaceable.

Use standard cable when:

- ✅ Fixed installation, never moves

- ✅ Occasional movement (<100 cycles/year)

- ✅ Easy and cheap to replace

- ✅ Downtime cost is minimal

- Savings: 80-95%

Upgrade to high-flex when:

- ✅ Continuous motion (drag chains, robots)

- ✅ Lifetime cycles >100,000

- ✅ Replacement is costly or difficult

- ✅ Downtime cost >$500/hour

- ROI: Often 100-1000x

The calculation is simple:

If (cost of one failure) > (high-flex upgrade cost)

→ Buy high-flex

If (expected failures × replacement cost) > (high-flex price)

→ Buy high-flex

Otherwise → Standard cable is fine

Three golden rules:

- Calculate actual flex cycles - Don't guess, do the math

- Consider total cost - Not just cable price, but replacement + downtime

- Install properly - Even the best cable fails if installed wrong

Most common mistake: Using standard cable in continuous flex applications to 'save money.' The first failure costs more than 10x the price difference.

Second most common mistake: Using premium high-flex in fixed installations where standard works fine. This wastes 80% of your budget.

Match the cable to the application, and it will last its designed lifetime.

Now you know when to upgrade and when to save your money. Make the decision based on your actual requirements, not on sales pitches or false economy.