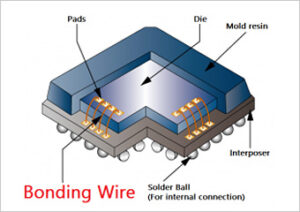

In your smartphone, laptop, or any electronic device, the chip is the brain. But what you might not know is that for this 'brain' to communicate with the outside world, it relies on a critical connection process: wire bonding. It's how tiny metal wires create bridges, connecting the chip's internal circuits to the outside pins of its package.

what is bonding wire

This article will break down wire bonding, a vital process in semiconductor manufacturing. We'll explore its basic definition, key materials, and working principles to help you understand its essential role in modern electronics.

Wire Bonding: The Bridge Between a Chip and the Outside World

Simply put, wire bonding is the process of using extremely fine metal wires—called bonding wires—to connect the pads on a semiconductor chip to the leads on its package or substrate. This process must be incredibly precise, as these wires are often thinner than a human hair, and there can be thousands of them on a single chip.

Wire bonding is a crucial step that ensures the chip functions correctly, signals are transmitted reliably, and the device's electrical performance is stable. The quality of this process directly determines the chip's overall reliability and lifespan.

The Lifeline of Wire Bonding: Bonding Wires

Bonding wire is the thin metal filament used in the wire bonding process. Its diameter typically ranges from 15 to 50 micrometers. Depending on the application's needs and cost constraints, there are three main types of bonding wire: gold, copper, and aluminum.

1. Gold Bonding Wire

Gold has been the historical standard and is the most widely used material for bonding wires.

- Pros: It offers excellent electrical and thermal conductivity, is highly resistant to corrosion, and is very easy to bond. Its thermosonic bonding process is exceptionally stable and reliable, making it the ideal choice for high-performance and high-reliability applications.

- Cons: Its high cost is its biggest limitation.

2. Copper Bonding Wire

As gold prices have risen, copper bonding wire has emerged as the primary alternative.

- Pros: It is significantly cheaper than gold wire and has better mechanical strength and conductivity.

- Cons: Copper is prone to oxidation at high temperatures, which makes the bonding process more challenging. It requires specialized equipment and a protective gas environment to prevent oxidation.

3. Aluminum Bonding Wire

Aluminum bonding wire is a common choice, especially for high-power semiconductor devices.

- Pros: It is very low-cost and has high hardness, which is beneficial for bonding in high-current applications.

- Cons: Aluminum bonding requires higher pressure and force, which can potentially damage the chip. Also, the bond reliability is lower when bonded to gold pads, which can create a brittle intermetallic compound.

The Wire Bonding Process and Equipment

Wire bonding is typically performed by an automated wire bonding machine. The process generally involves three main steps:

- First Bond: The machine forms a secure ball bond on a chip's pad using a combination of heat, pressure, and ultrasonic energy.

- Looping: The wire is then pulled into a specific loop shape to prevent it from touching other components.

- Second Bond: The wire is attached to the package lead using a stitch bond, completing the connection.

The precision of this process is a testament to the quality of the equipment and the workmanship of the manufacturing process.

Quality Workmanship: The Foundation of Reliability

In microelectronics, the term 'workmanship' refers to the skill, care, and quality that goes into making a product. When it comes to wire bonding, excellent workmanship means:

- Secure Bonds: The connections are strong enough to withstand thermal expansion, contraction, and vibrations without breaking.

- Consistent Loops: The wire loops are uniform in height and shape, which prevents short circuits.

This concept is similar to a ground wire in an electrical system. Just as a ground wire provides a safe path for excess current, high-quality workmanship provides a reliable and safe path for signals and power, ensuring the overall integrity of the device.

Conclusion

Wire bonding is a critical, yet often unseen, hero in modern electronics manufacturing. The right bonding wire, a precise wire bonding machine, and superior workmanship are all essential for a chip's performance and reliability. Next time you use an electronic device, you can appreciate the thousands of tiny 'lifelines' working seamlessly inside.